|

Hard to see much from this photo but what I have done is

to imbed the hinge screws and cover them with filler. Since past

experience has proven that simply filling the area of the screws will

eventually show through, I have filled holes and the low spots with

SuperFil and covered everything with a ultra-fine layer of lightweight

fiberglass. This should protect the screws and provide a very

good layer for final finish. I am very near complete with the

ailerons and ready to prime for painting. |

|

I tried to

setup a paint booth in my shop at home to paint the wings, ailerons,

flaps, and other small parts. It worked but was far from the best

and I didn't have adequate ventalation.

|

|

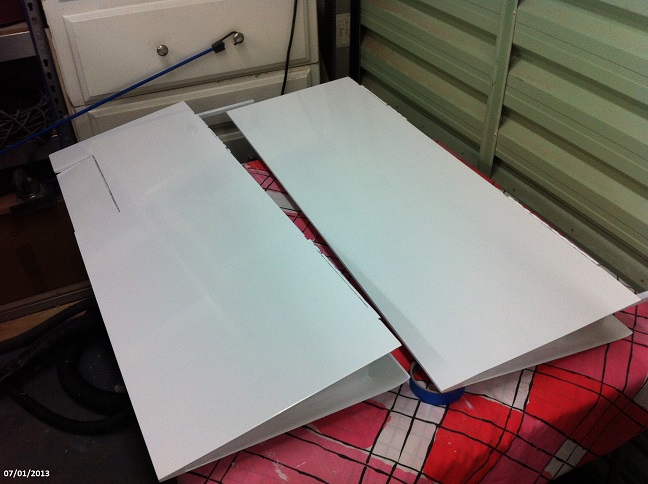

The completed Ailerons

can be seen in this photo with what was my initial attempt to paint the

plane but which proved to be a big mistake and a huge waste of

time. The paint did not properly bond to the primer and peeled of

like tape. I later found out that the reason for the failue was

my own. I had primed the parts months before application of the

final coats and they failed to bond to the old primer. That's

what happens when you don't have time to complete processes in a timely

manner.

|

|

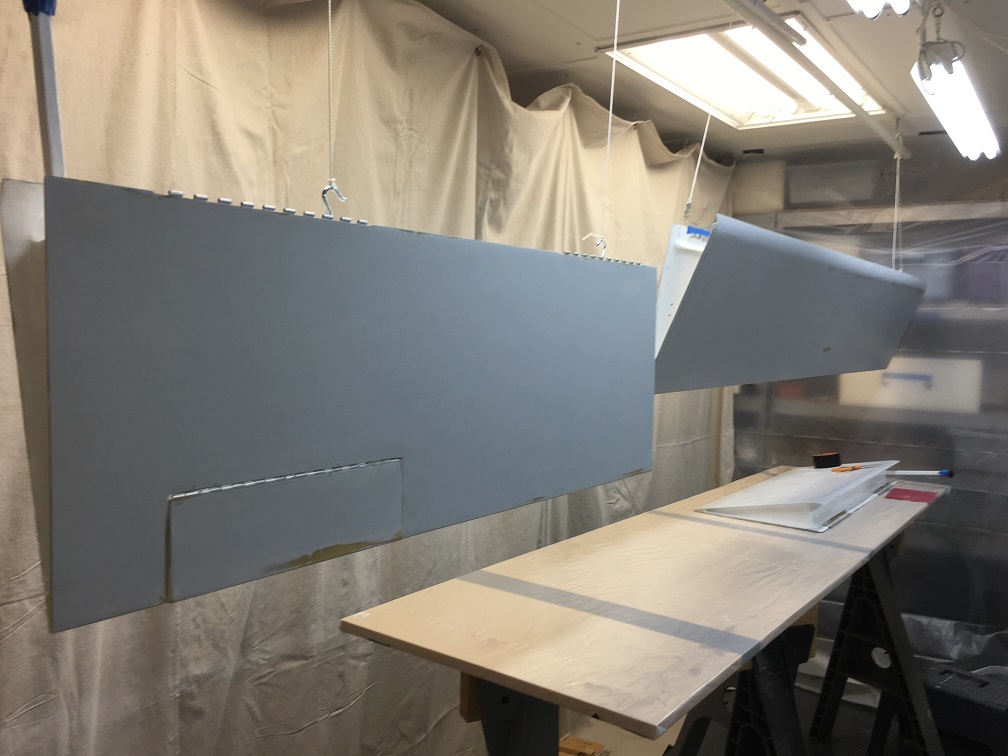

On

my final attempt to paint the plane, which spaned several years, I

setup a paint booth at my hangar and installed a bank of fans on one

side and filtered inlets on the other side. I had to rent a gas

powered compressor to perform the painting but I finally got everything

painted.

|

|

Mounting the

ailerons was quite a task since the hinges are hidden and require a

painful and time consuming process to install. I wrote a separate

section on the installation process.

The right side aileron is shown.

|

|

The left side

aileron includes an electric trim tab.

Looks pretty good if I must say so.

|