|

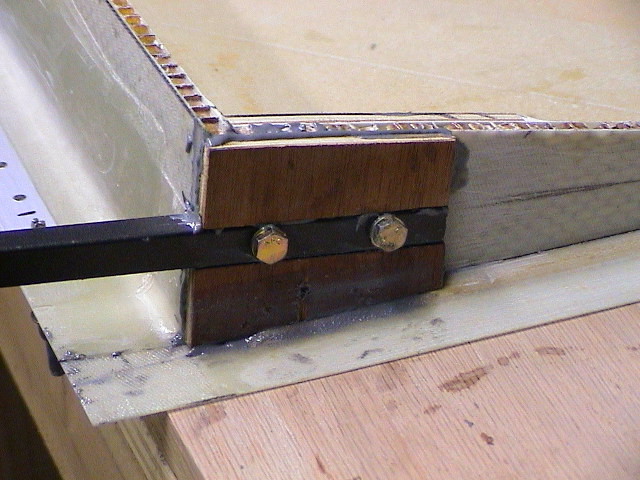

Never one to follow the directions I put a little extra

support on the counterbalance rod. |

|

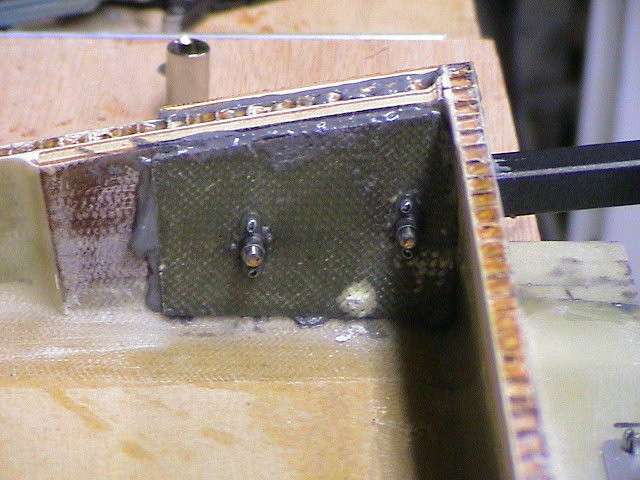

The nut plate is bonded to the inside. |

|

I also used a nutplate for the aileron control horn.

The bonding agent is the Aero-Poxy Adheasive which is a

very strong and great adheasive which has the added benefit of having a

1-1 mixture ratio. It makes it very easy to mix small amounts for

small parts bonding.

|

|

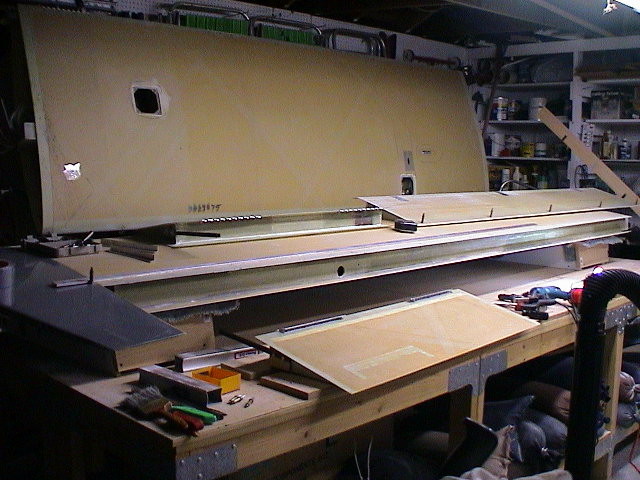

I mounted the hinges to the Aileron first using a straight

edged for alignment. They are initially mounted to the outside of

the aileron. |

|

I used a straight edge to help cut the hinge slots in the

trailing edge. Before fitting the aileron I positioned the wing

tip and clecoed it into place as a guide for positioning the aileron. |

|

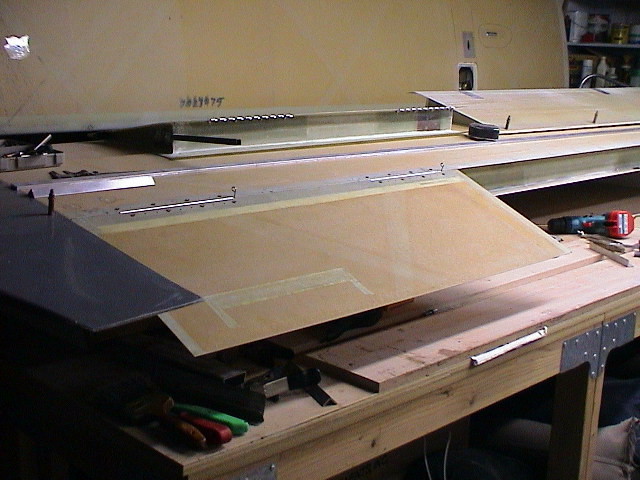

Using pieces of aluminum angle for a spacing guide to help

with alignment. They are taped into place to prevent them from

moving. |

|

The aileron is then positioned and carefully taped into

the proper position. The edges were all double checked and then

the holes for the hinges were drilled. |

|

After the holes are all drilled, the hinges are

repositioned to the inside of the wing and aileron. The aileron

is perfectly positioned. I am using removable hinge pins which

makes the whole process much less time consuming. |

|

The next process is to trim the ribs and spar until the

aileron swings freely without binding on the bottom. Duct tape is

your best friend during the time consuming and very repeatative

process. |

|

Close out! I used a nice flat piece of plywood to

help remove a slight bow to the bottom of the aileron. |