|

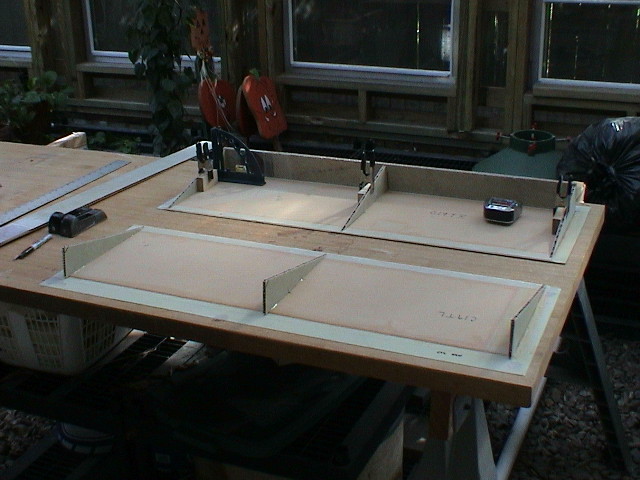

The parts for the ailerons have all been cut and trimmed

to the diminsions as indicated in the manual. I made two

hardboard templates for the ribs and then trimmed all the interior ribs

to match those templates. The top skins have been tacked to a

solid core door with 5-minute epoxy to provide a flat surface. |

|

The position for the spar and ribs has been marked and the

ribs tacked into place with a mix of 5-minute epoxy and flox. |

|

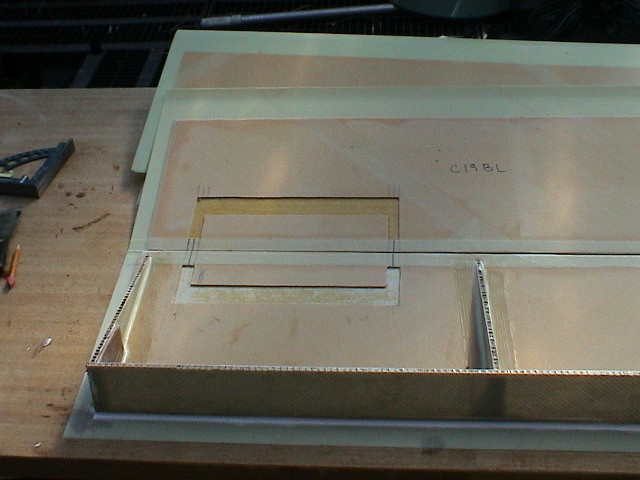

The ribs and spar have all been glassed into place.

The control horn block is located to fit with the control shaft

on the wing. (Make sure you trial fit before you glass or double

check to ensure you have the mounting block in the right position.

Note the extra 1/4 inch block on the outside rib for mounting the

counter weight. |

|

The front of the spar has not been glassed yet and will

not be until the top (or bottom in this case) has been bonded.

PS: The trashy looking work area is actually my

greenhouse attached to the back of the garage. It makes a great

work area in the spring and fall but is full of plants in the winter

and too damn hot in the summer.

|

|

I marked out and prepared an area for a 12 inch long by 3

inch aileron trim tab. The area has been cleared out and is ready

to install the forms for the tab. |

|

I used the pattern and cut four small ribs and a couple of

spars and positioned them with the 5-minute epoxy/Flox mixture.

These will be glassed with a 1/2 inch bid and bonded to the

bottom before being cut out. |

|

I couldn't believe it but a trial fit of the bottoms and

everything including the trim tab fit like it was intended and after

only two days of work.

Some days we just get lucky....or could I actually be

getting good at this stuff.

I will use 5-minute epoxy to tack the bottom in place

temporarily while I check the aileron to the wing to make sure it has

proper fit and clearance for the bottom once hinged and installed.

|

|

Page 2

|