|

The

area under the the back seat between the seats is used for a pass

through of all wiring, controls, and the attachment of the linear

actuator flap control. The opening the the back seat bulkhead is

very tight for all the stuff that eventually passes through the opening.

|

|

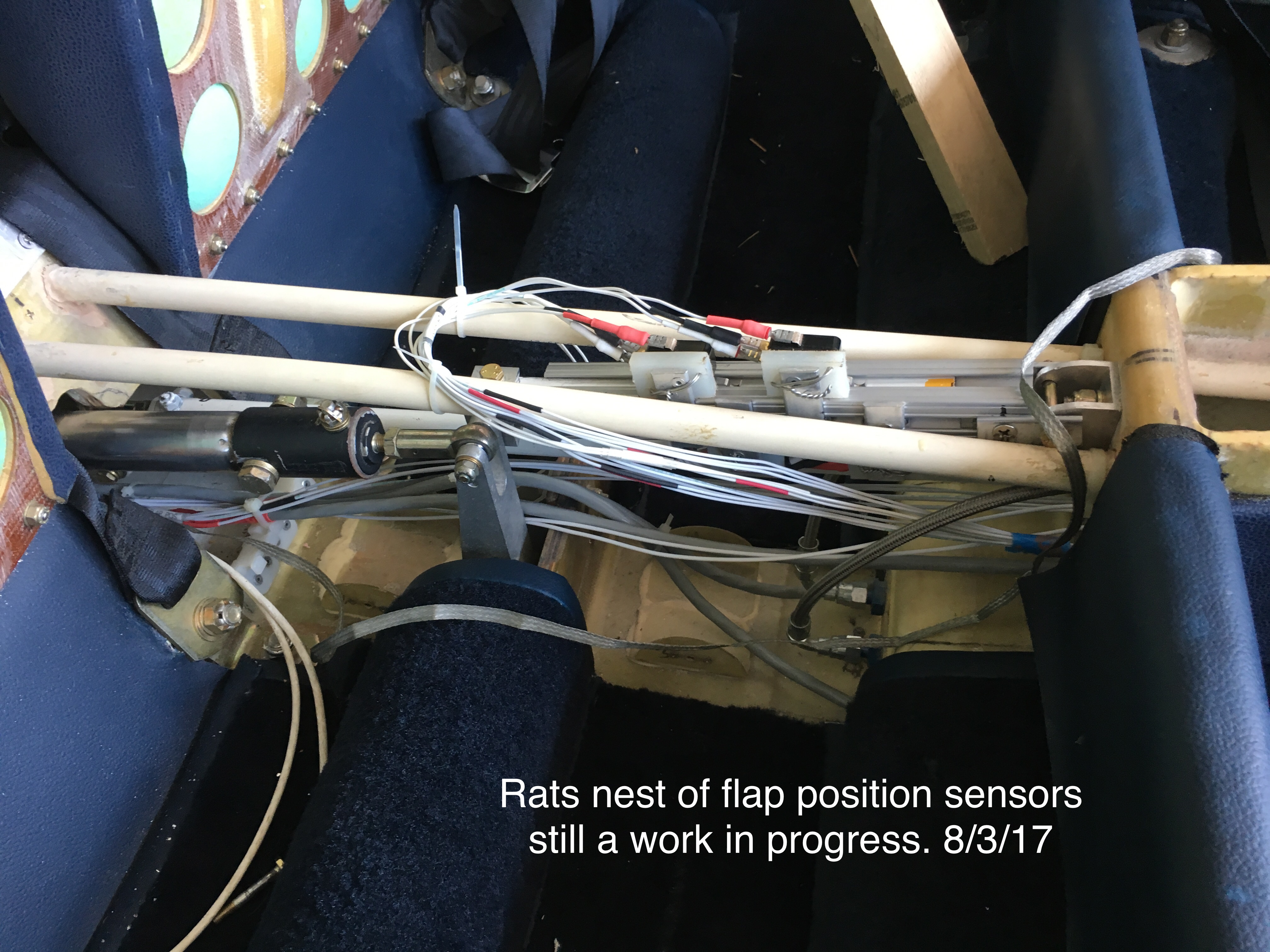

Directly

behind the back seat I put in the mounting pints for the strobe

controller and the flap motor. The photo show the idler arm for

the elevator control. This will all be covered with a tunnel

cover.

|

|

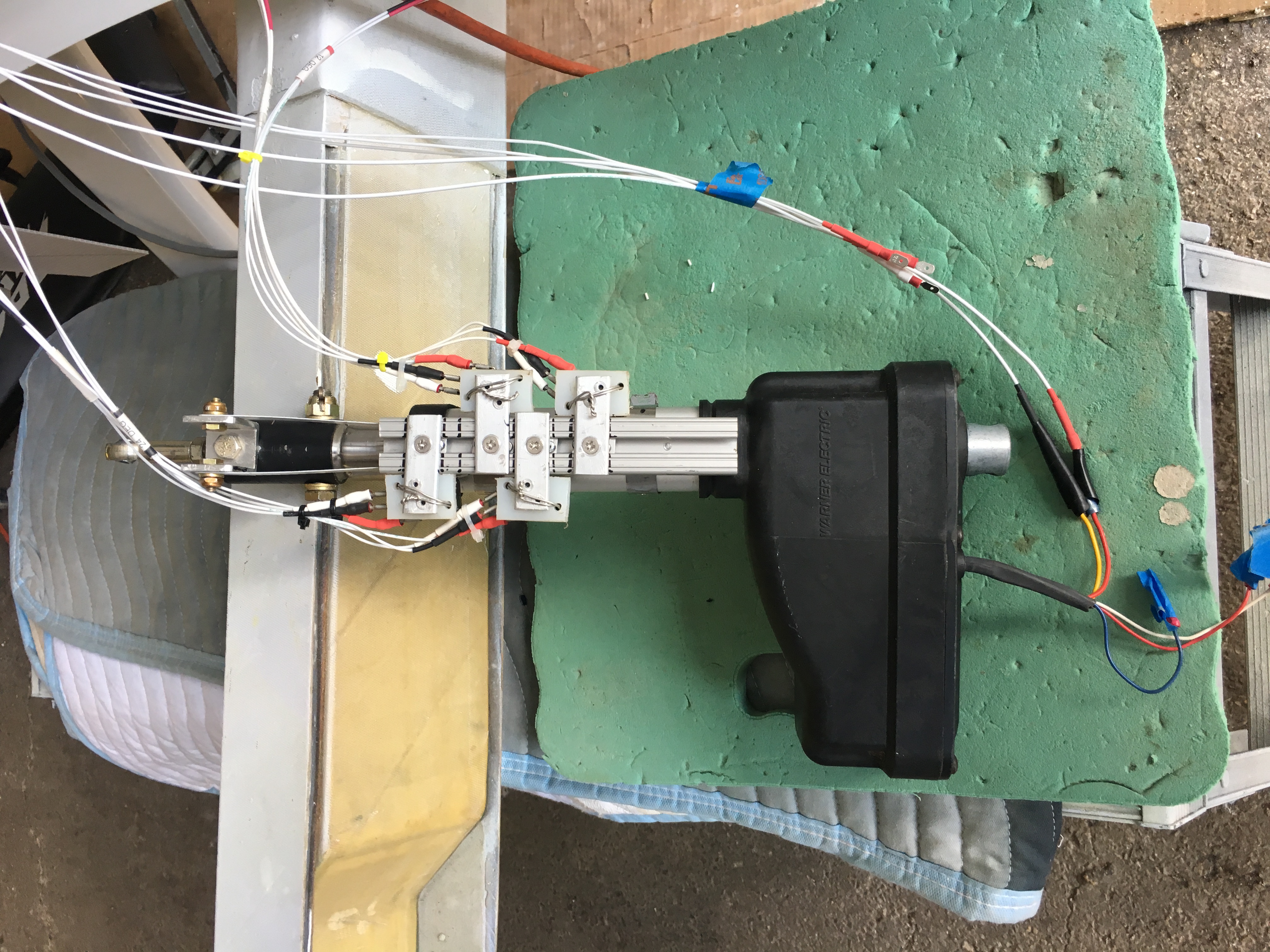

I

used a linear actuator from Warner Electric that was supposed to

contain internal limit switches. When I eventuall got around to

the installation process I discovered there were no internal limit

switches but have a build in position sensor. Not usable in the

long run.

I decided to use limit switches

installed into a channel connected to the actuator and tripped by a

pair of hack saw blades (Saw part removed). The limit switches

were rather large and resulted in the requirement for them to be

alternated on either side of the channel.

|

|

Each of the switches required three wires and the actuator contained another five wires. A lot of wiring.

|

|

The

completed setup looks rather complicated but isn't as bad as it looks.

The issue was that once I installed the flap actuator the portion of

the actuator that stuck thru the rear seat bulkhead put the switches in

the opening thru the bulkhead. It just wouldn't work with the

needed movement during extending and retracting the actuator.

Time to go back to the drawing board.

|

|

The

tight quarters for installation of the flap motor, the elevator push

rods, and the strobe lights controler can be seen but it got worse when

all of the additional wiring, pitot, static, and other lines were run

through the same space.

|

|

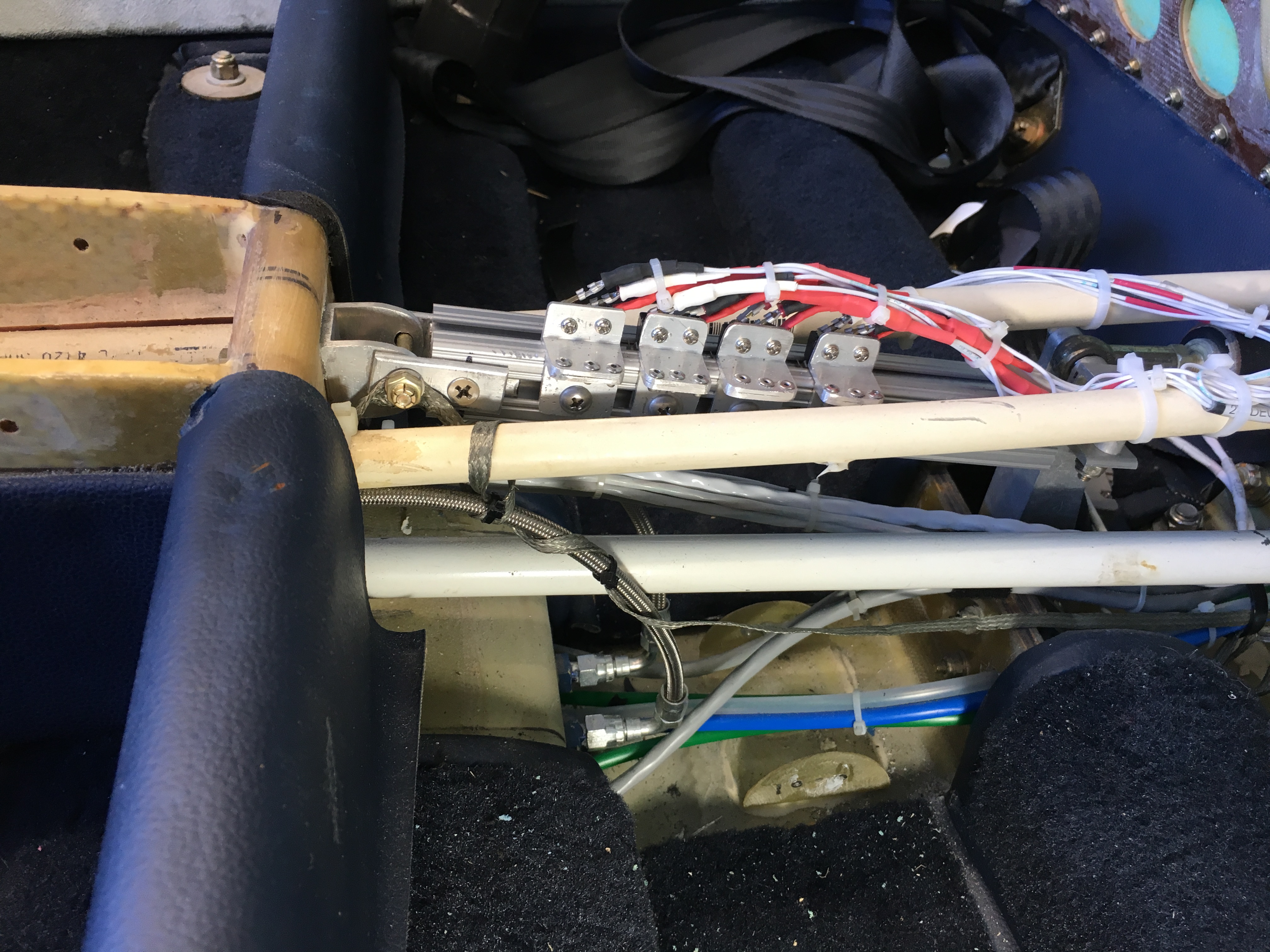

I

move the flap control switches to the area between the seats and turned

it sideways. This was very tight with the switches being on the

top and the bottom. Worked but the wiring was a nightmare even

though it did reduce the number of wires that had to pass through the

bulkhead opening.

|

|

Well,

everything is connected and the wiring in place. With enough wire

ties and adjustment I was finally able to get everything tied down and

the switched adjusted to position the flaps. OR SO I THOUGHT!!!

After hours and hours of

work to get everything positioned and the wiring done I was able to

accurately position the flaps at the full retracted, 12, 24, and 36

degrees. I started testing and testing but something wasn't

right. The positioning down was working perfectly but about half

the time, the flaps would not return to the up position. That's

when I realized that the front lower switch had cracked and

broken. I just wasn't happey with the whole thing and ripped it

out and started over.

|

More to Come...it does get better.

|

The concept was good but the Execution Stinks.

|

|

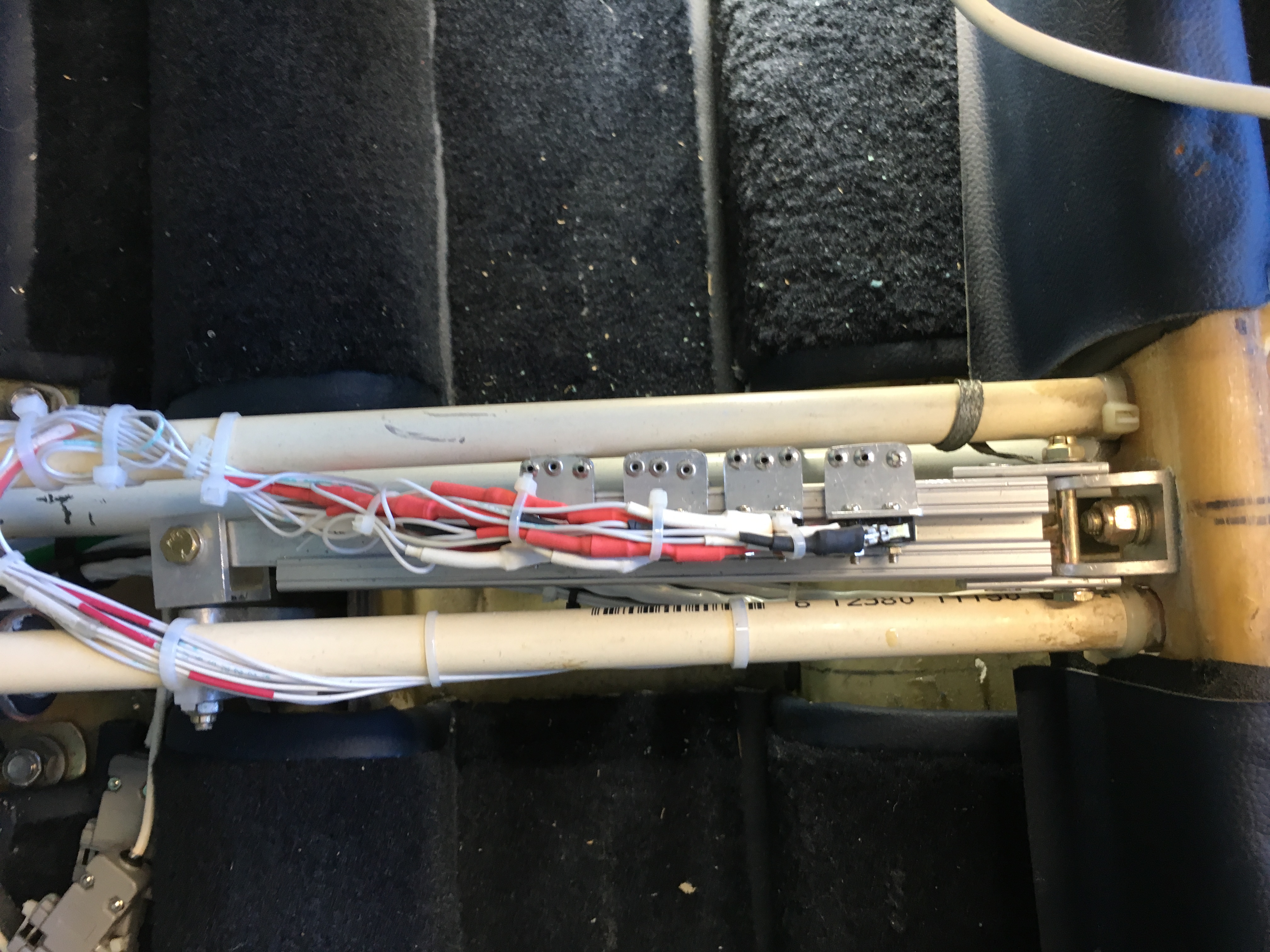

The

rebuild flap control unit can be seen installed using the much smaller

micro switches. I had to redo all of the connectors to the

switches since the original switched used the .25 inch push tabs while

the new switched use the .187 tabs. They are much smaller and allowed

all of the switched to be installed on one side.

|

|

A

top view shows the tight formation and how the switches sit directly

over the open channel. The switches are triggered as a thin

aluminum blade slides up the center channel.

|

|

This

view shows the switch mounting tabs and their connection to the side of

the channel. The tabs are held in place with a screw that

connects to a tab inside the channel.

This system works exactly as I had wanted it to and allows for easy adjustment of the flap position.

|