|

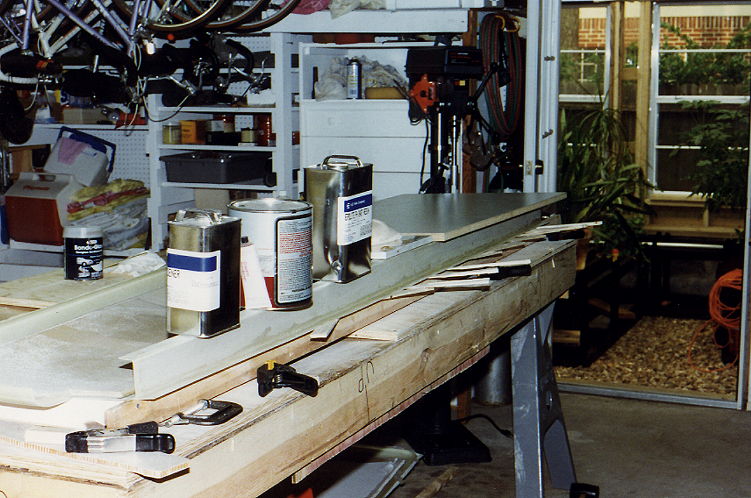

Once separated, the top of the stabilizer is mounted on the work area

and the rear spar positioned and bonded into place. |

|

The ribs, which are cut from flat prepreg panels, are

then positioned, checked for proper fit, and glassed into place. |

|

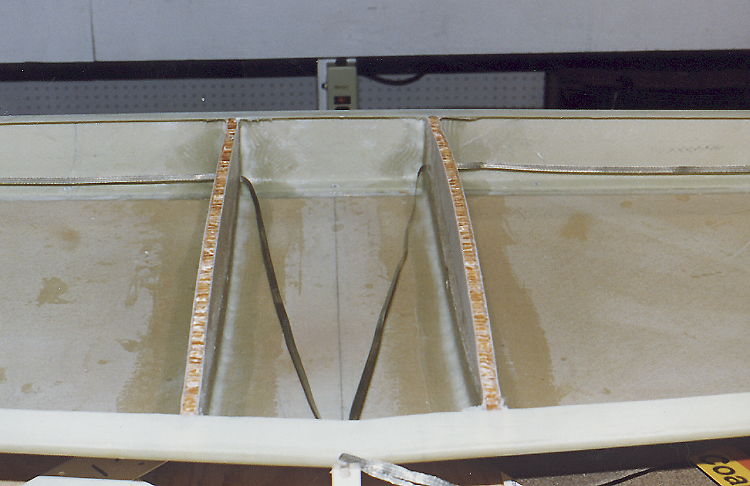

Once all the ribs are glassed in place, they are trimmed to fit with

the bottom panel. This shows the ribs prepared to receive the epoxy/flox

mix for joining to the bottom stabilizer panel. Shown also are the

electrical bonding ground wire which I chose to include. This is part

of a bonding wired that links all metal parts of the airplane. |

|

|

|

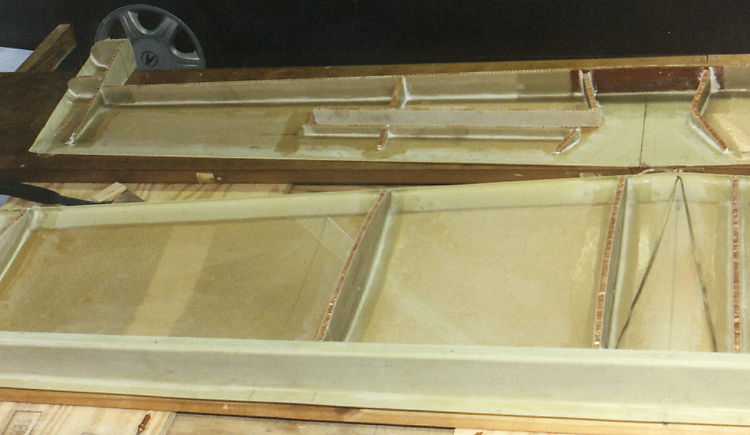

The above photos and left show the horizontal and vertical stabilizer

both ready for closeout. |

|

The stabilizer has been finished, the front edge and spar have been

covered with Hycell Glue, and the ribs have and epoxy / fox fillet for bonding

to the bottom panel. Everything is ready for final closing of the

Horizontal Stabilizer. |

|

The above is a close up of the epoxy / flox fillet just prior to close

out. The inside of the bottom panel have been painted with epoxy and

glue spread on the leading edge and spar joints.

|

|

A lot of clecos, some lead, several bundles of shingles and you have

enough weight to close out the stabilizer. |