| The cowl is modified from the original Cruiser cowl. The

Nasa vent supplied with that cowl could not be used as it did not line up

easily with fuel injector unit of the Lycoming IO 360 200hp engine. I had

to fabricate an air intake spout but it fits directly up to the air filter

which has a rubber baffle so that the large diameter scat tube which is often

used to connect the air inlet of the cowl to the filter (and which is usually

very difficult to fit when replacing the cowl) is not required. Whilst modifying

the cowl I incorporated twin landing lights. The lights are 50 amp. automobile

spot lights. One of the problems with cowl mounted landing lights is that

wiring connections have to be disconnected when the cowl is removed. Usually

one forgets to disconnect them and the wiring is broken on removal of the

cowl. We have eliminated that problem by connecting the live and ground wires

to the piano hinges which hold the cowl to the firewall. As the pin is removed

from the hinge the connections are automatically broken and are restored

when the pin is re-inserted. |

|

|

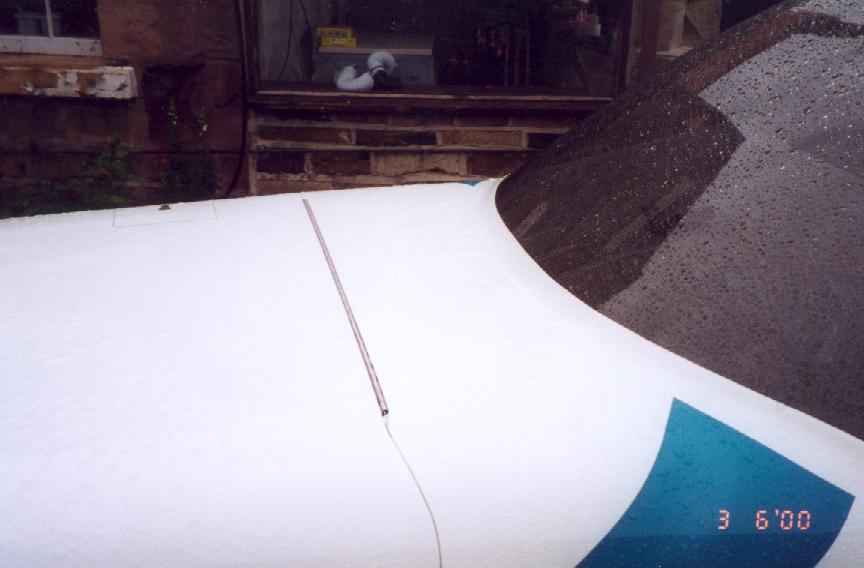

| The cowls are held in place with four screws and five piano

hinges. I make no claim to originality for this method, it is widely used

on RV’s and is described by Tony Bingelis. It does produce nice clean

lines and makes the cowls very easy to remove. The only hinge which is visible

is the one across the cowl in front of the windscreen. Fitting it that way

makes it possible to raise the upper cowl for inspection without removing

it. If the upper cowl is held with multiple screws the temptation is not

to remove it very often to inspect hoses etc. The screw at the outer side

of the air intake attaches to the end of the piano hinge wire. When unscrewed

the wire between the upper and lower cowl can be removed |

|

|

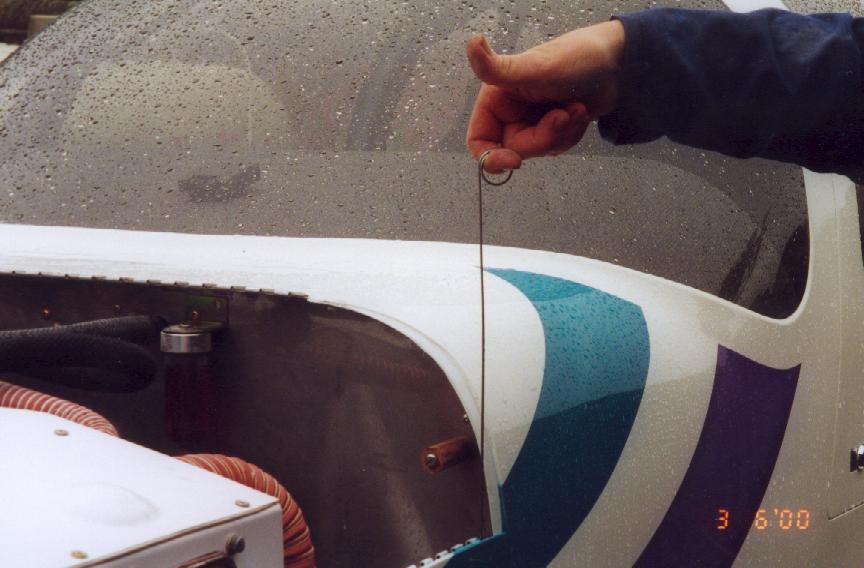

| With the two pins and the two additional screws removed

the cowl can be hinged upwards. |

|

|

| The transverse pin and upper cowl are easily removed. |

|

|

| The pins for the lower cowl to firewall hinge are located

on long Tufnol rods which prevent them vibrating loose. They

are withdrawn simultaneously (a two-man job – difficult when one man

is taking the photographs) |

|

|

| The half hinge mounted on the firewall flange can be seen.

It has a double curvature and requires some filing and rounding of the hinge

segments on the curve to allow the pin to enter smoothly. |

|

|