To prevent the risk of buckling in the elevator push rod and to reduce the tendency to vibrate we decided to divide it into two lengths with an intermediate idler.

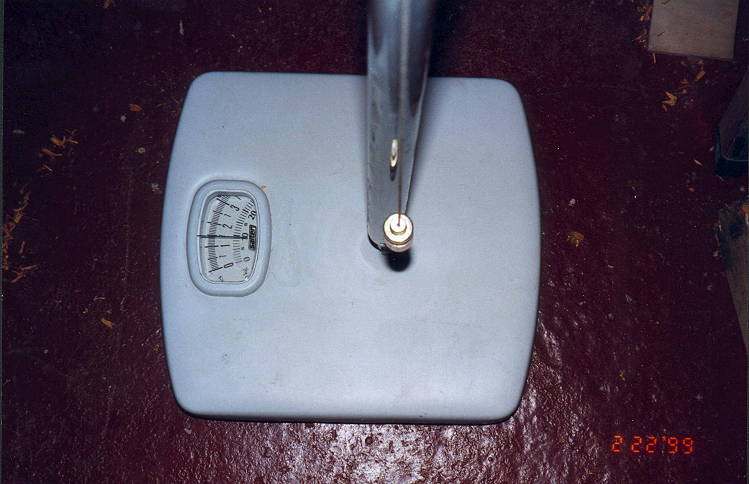

rod was measured on a weighing scale

at 15lbs

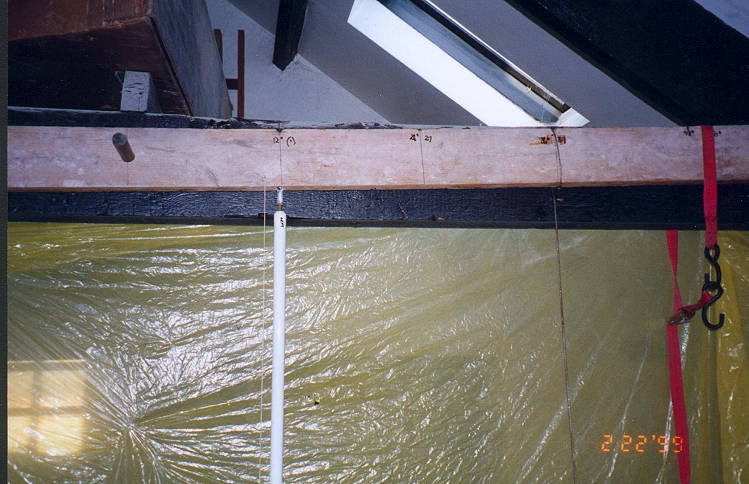

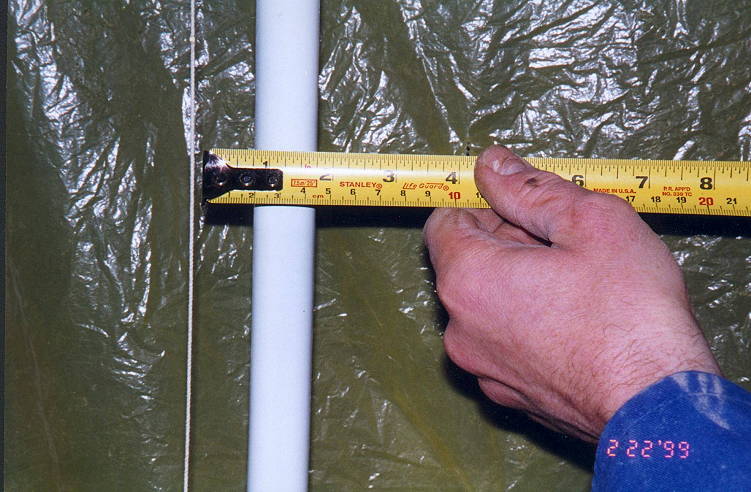

In the wing the tube runs in the D-box which is approximately 3"x3½". This restrains the tube as it bends and so prevents buckling The test was repeated but on the second occasion the tube was placed inside a 3" diameter plastic drain pipe. The 56lb weight was moved to four feet from the fulcrum and the tube supported a total weight of 239lbs. Sufficient to satisfy PFA