|

|

|

| Above: The wiring and pitot lines are

installed in the same area as the aileron bell crank. Kind of

crowded in there. Note ground wire and plastic sheet to keep

things clean.

Right and Above Right: The retractable

tiedown. The tiedown is mounted to a glassed in plywood insert

with an aluminum angle on the inside to spread the load. (Overkill?

Maybe but it will be very hard to get into this area if there is

ever a problem so I would rather be safe.)

|

|

|

|

|

|

|

Above and Above Left: NAV Antenna

installation with one arm cut through Rib. Antenna in riveted in

place.

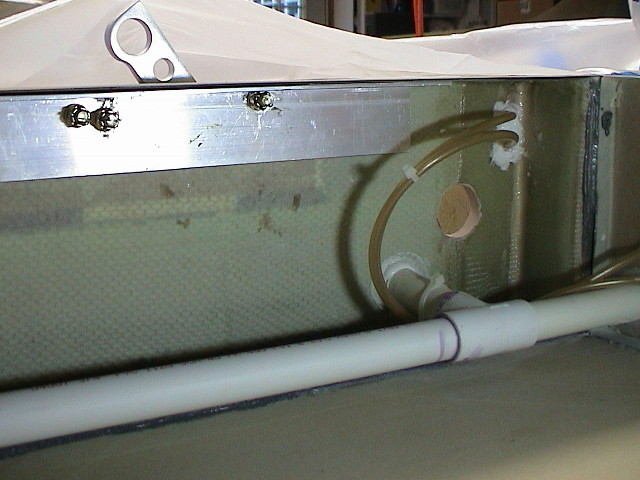

Left and Below: Jeffco 9700 sealed fuel bay.

Left shows uel filler with vent line in corner. Fuel level

sensor is the long tube running between bay one and two. Vent

between bay 1 & two is in lower corner of bay 1 through rib to

upper corner of bay two. Fuel sender is permanently glassed in

place.

|

|

|

|

| Right: Lower wing with opening for Pitot

installation, cutout for retractable tiedown.

Below and Below Right: Jeffco 9700 Sealant

and inspection cover for spar bolt installation. Everything is

ready for the close out.

|

|

|

|

|

| Below: The secret to a good closeout is

preparation! Before starting the closeout I had sanded everything,

washed and wiped down everything. I had covered the fuel bay with

plastic to keep it clean. Just before closing I did an Acetone

cleaning and allowed to dry. I measured out all adheasive and had

everything ready before starting. It took three of us two hours

from start of mixing to completion of last stepping stone weight.

Part of the supplies were an old plastic bowl for mixing large

amount of adhesive. Also, three 1" paint brushes with the

bristles shortened to make application easier. |

The close out started by mixing one batch of adheasive

with NO filler. This was painted on to all areas to be bonded,

both top and bottom. This was the wet out. Next mix the

remaining adheasive with flox (or milled glass) to form a thick mix.

It should be thick enough to not run off the area to be bonded.

I used cake decorating bags to apply a half inch bead to all

areas and then spread that out with a squeege. The front edge was

clecoed while hold the wing from contacting. Weight was added

from the front edge with contact starting from the front to back.

A lot of weight was placed on the front. |

|

|

|