One main point

here is that the front and rear rib sections are all the

same. Because of the positioning of the flange is the only

difference

between the left and right wings, you can prepare all the rib sections

at

one time without being concerned about left or right.

I made a couple of jigs and then proceeded to prepare all the rib

sections

in advance. It made for a very quick and easy operation.

The following

shows some of the details of the operation. |

|

|

|

|

I fabricated a quick jig for positioning of the holes

for the electrical conduit and for the pitot lines.

The jig was made from 5/8 in scrap board left over

from the wing jig construction. |

Due to the installation of the ribs being the

same on both sides, the holes can be place in

the same position on all the ribs at once. |

|

I used plastic gromets with a 1/4 inch inside

diameter and bonded these into each of the

holes for the pitot lines. The cavity on the

inside of each gromet is then filled with

silicone sealant once the pitot lines are

installed. The result is secure pitot lines

without binding or rubbing against the sides

of the glass ribs. It is also a very flexible

installation and allows the lines or the wing

to flex. |

|

|

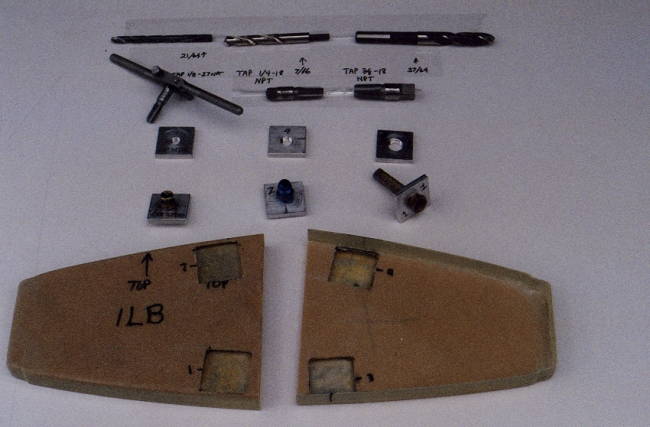

The two inside ribs of the fuel bay will need one or

two aluminum inserts for the fuel outlet and return

lines. These are fabricated by the builder and then

glassed into place. These ribs are also cut short

by three inches for clearance of the main spar. |

The above shows the required drill bits and

threading dies required for fabrication of the

fuel outlets. My personal opinion is that I

would have been glad to pay extra for these

to be fabricated by the factory. |