|

The

left wing tip has been installed with clecos and an epoxy bonding

paste. I removed the clecos BEFORE the epoxy cured this

time. I failed to do so on the right wing and it was a lesson

well learned on removing them.

|

|

Front

view of the wing tip with the clecos still in place but I have started

removing them. The epoxy was still soft but was cured enough to

not allow the wing tip to move. If I had been really smart, I

would have used a razor blade to trim the soft epoxy before total cure.

|

|

Cleaned

off the bonding epoxy residue and started the leveling and filling of

the joint between the wing and the wing tip. Took a bit more

filler than I had hoped but it isn't very thick and sanded out smooth

and level.

|

|

Took

a photo of the bottom before I cleaned off the bonding epoxy

residue. That stuff is as HARD as a ROCK but had to all be

removed. The best way to remove was with a straight edged

razor blade. It bonds the two surfaces but doesn't stick to the

smooth surface of the wing tip.

|

|

I

have scrapped off the bonding epoxy and done a bit of sanding. At

this point I will sand with 80 grit paper to make sure I have a good

bonding surface for the filler.

|

|

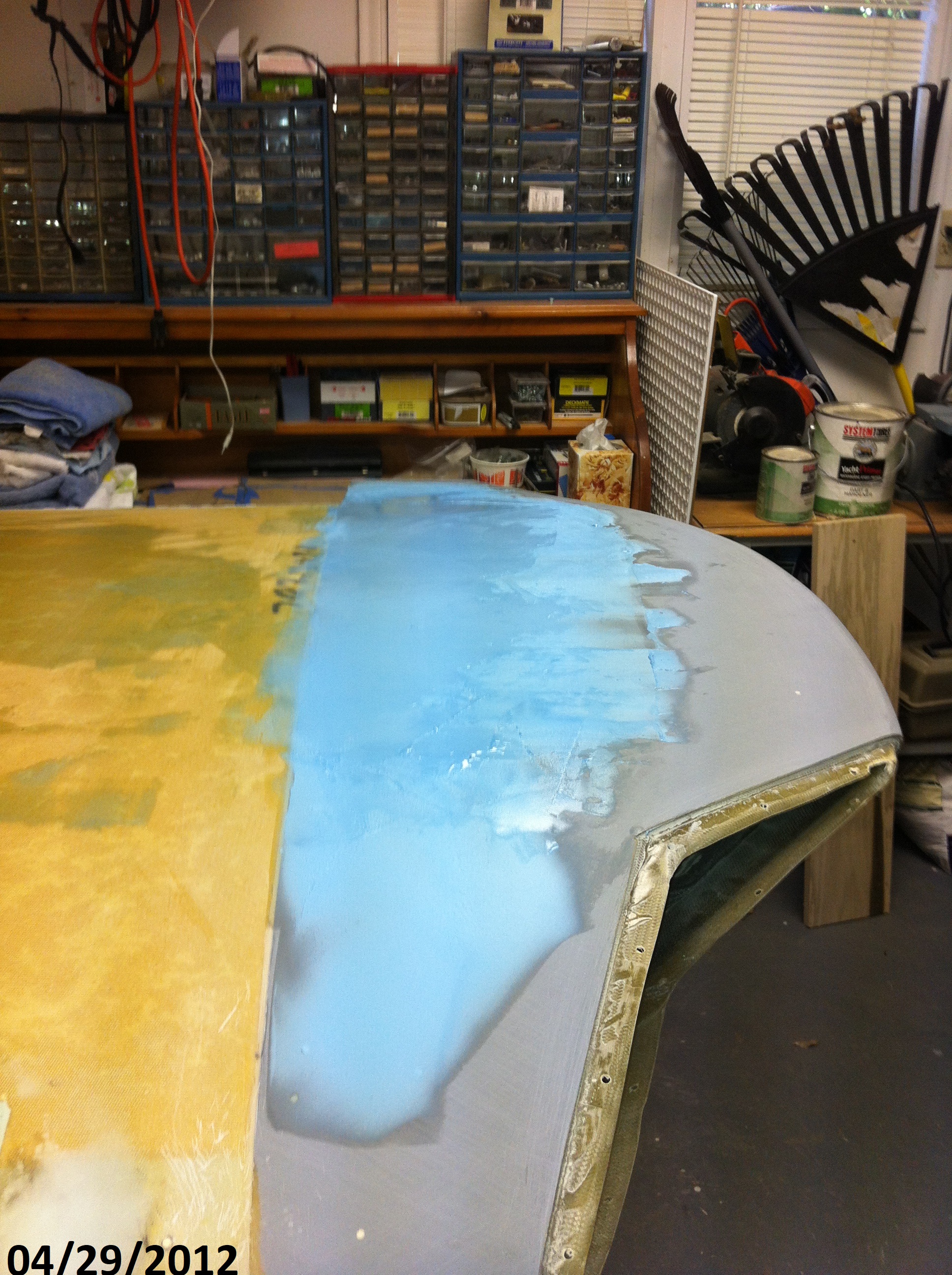

Sanded

the joint and applied the first coat of filler. I will sand this

down smooth and apply an additional coat of filler that is feathered

out several inches on each side of the joint.

|

|

When

applying filler the idea is to spread it out fully and then take it off

until you have a smooth level surface. Check it and repeat until

you have a clean level surface.

|

|

I used the filler to fill in the cracks and

smooth the contact area around the wing tip running lights opening.

|

|

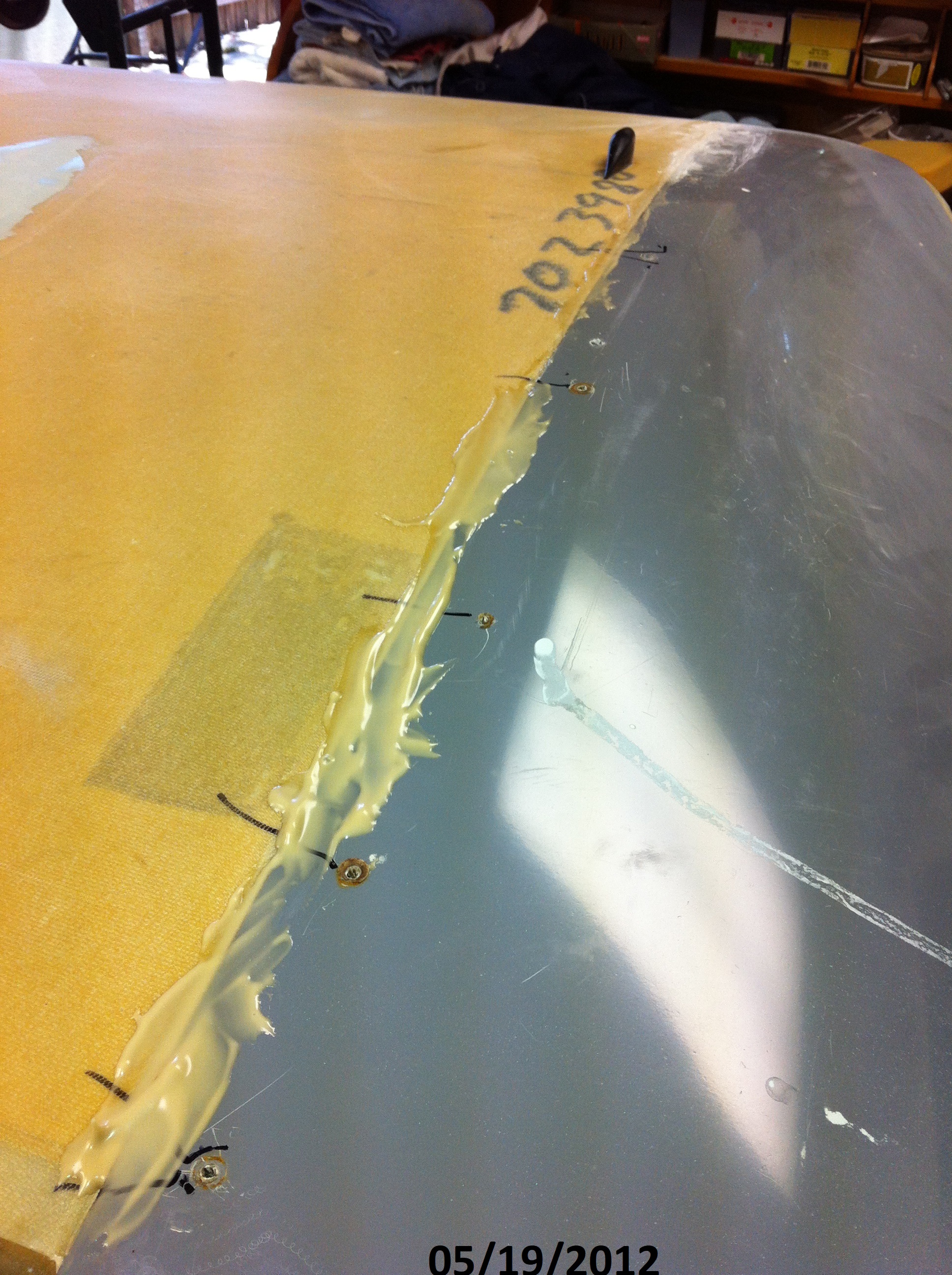

In

my research on finishing the large surfaces I came accros a

recommendation for using a very light weight glass covering before

starting the final finish sanding and prime. I thought is was a

great idea and would give a much easier surface to finish since it

would be very uniform finish. This photo was taken after applying

the glass.

|

|

While

you can't see how smooth the finish is with the filler in place under

the light weight glass, you can see the variance in the thickness of

the filler by the difference in color. The thicker the fill, the

darker the color.

|

|

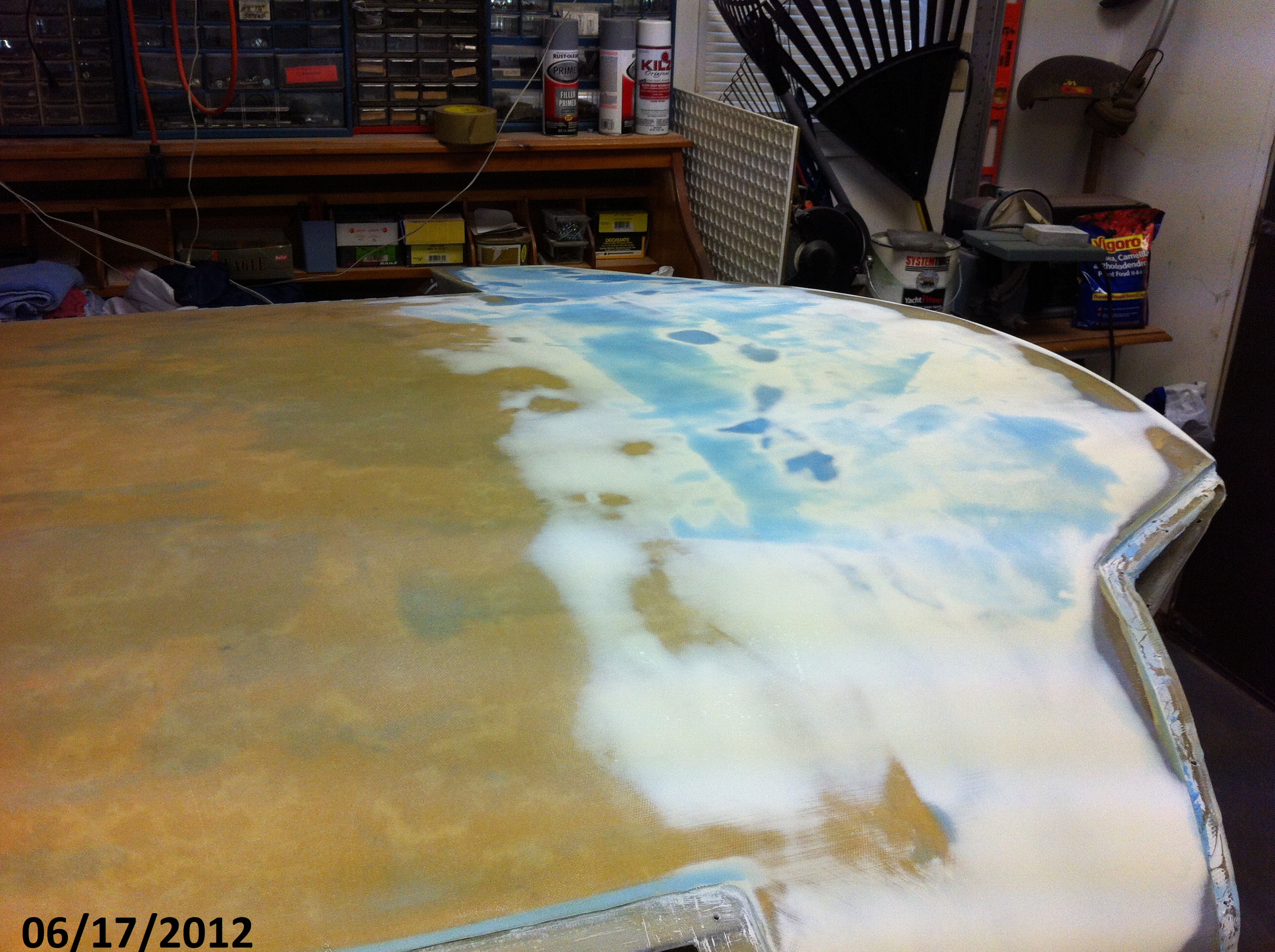

I

applied the 1/2 ounce glass on both the top and the bottom of the wing

with a full overlap on the leading edge of the wing. You can see

how thin the glass was at the opening for the running lights.

|

|

A very light sanding of the completed

surface after adding the light weight glass produces a surface ready

for primer.

|

|

The

rest of the wing tip photos are included with the wing photos.

The Final product doesn't show any signs of the wing tip being bonded

onto the wing. The final product with the position lights

installed looks great. (In my opinion anyway.)

|