Even this final paint process was NOT

without some additional

challenges. First problem was the lack of adequate electrical

power in the hangar. I had tried using the turbine units to apply final

coats of primer to the fuselage but couldn't get the three stage

turbine and the fresh air system to run at full power. I was able

to complete the application of the primer but not if I had any lights

on when trying to spray. I finished the primer application and

sanded it down in preparation for final color coats. I had made

arrangements for a guy who had been painting some local planes and was

a custom car painter to apply the color coats for me. He tried

using the turbine unit with the System Three Epoxy paint that I was

using. First problem was the lack of power to the turbine

units. Five minutes into the process, the circuit breaker

tripped. The circuit breaker was at the far end of the hangar on

the other side of the fence. Took 5 minutes to locate the breaker

and reset it. We cut off all other electrical except the turbines

and tried again but we didn't have enough power to atomize the

paint. Add to that, my painter had never used that type of paint

before and wasn't sure of how to thin it for spraying. We gave up

about 1/2 way through the first coat on the fuselage. Yet another

total failure. Add to that, my guy said he didn't want to

continue with the System Three paint.

|

|

|

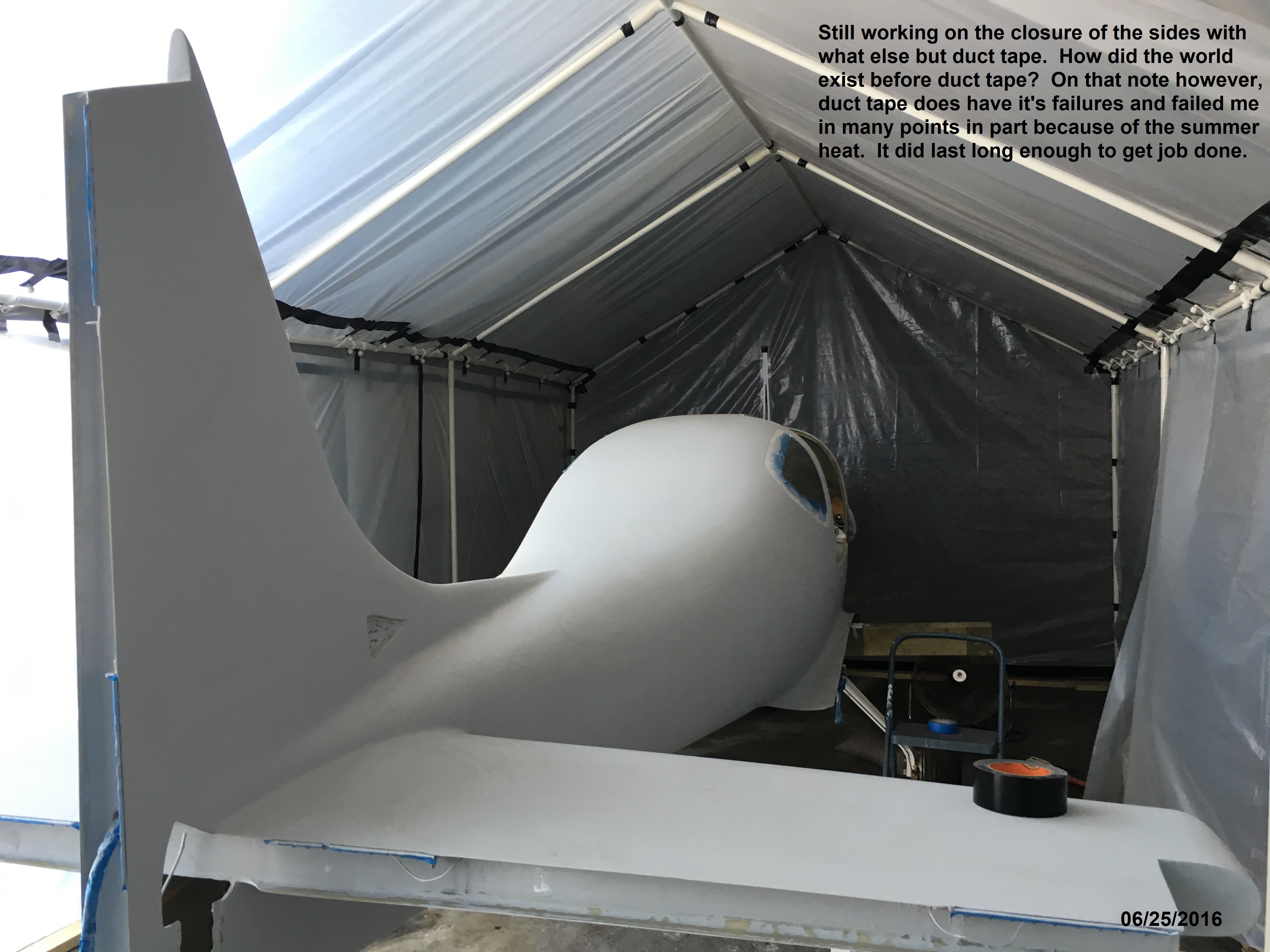

This is still part of the paint

booth assembly in the hangar. The side curtains are up and

connected at the top but the bottoms have not been anchored to the

bottom plate and the seams have not been taped.

|

|

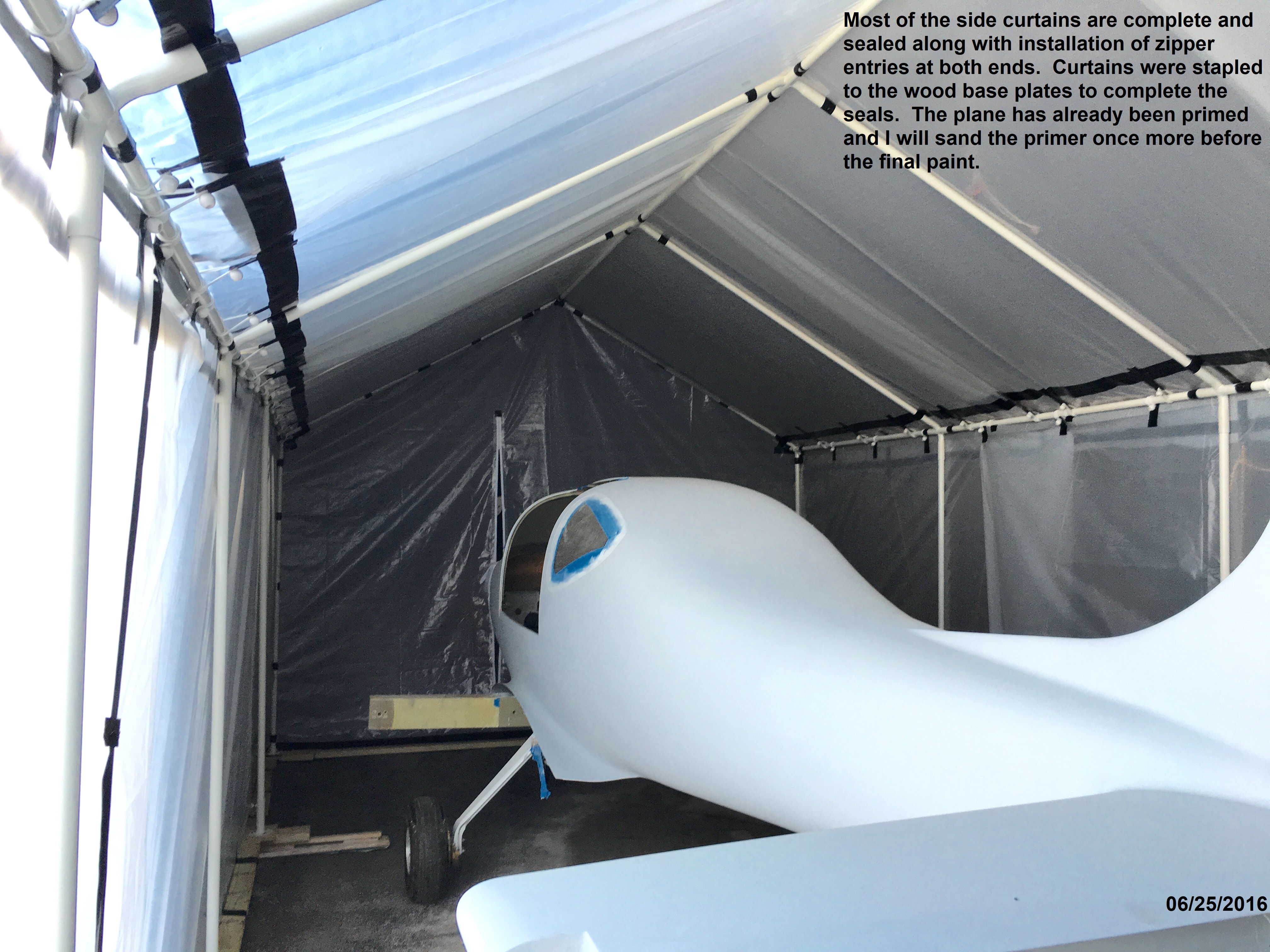

Still

working on the paint booth. Almost complete at this point ant the

ends have been tied down with the entry zipper put in place.

|

|

This

was the completed paint booth before the exhaust fans were

installed. I was afraid that the airport management was going to

come down on me for painting in my hangar but I later found out

they had zero problem with my setup since I had taken every precaution

to ensure that overspray would not get out of the paint booth.

|

|

I

was concerned about both paint escaping the booth and paint getting on

the floor so I covered the bottom of the paint booth with plastic

sheeting. Then I placed a cardboard covering over the plastic,

not to protect the floor but to keep from having the paint form a

sticky surface on the plastic. The cardboard absorbed the paint

and kept the plastic from getting torn. This shot also shows some

of the lights along the side.

|

|

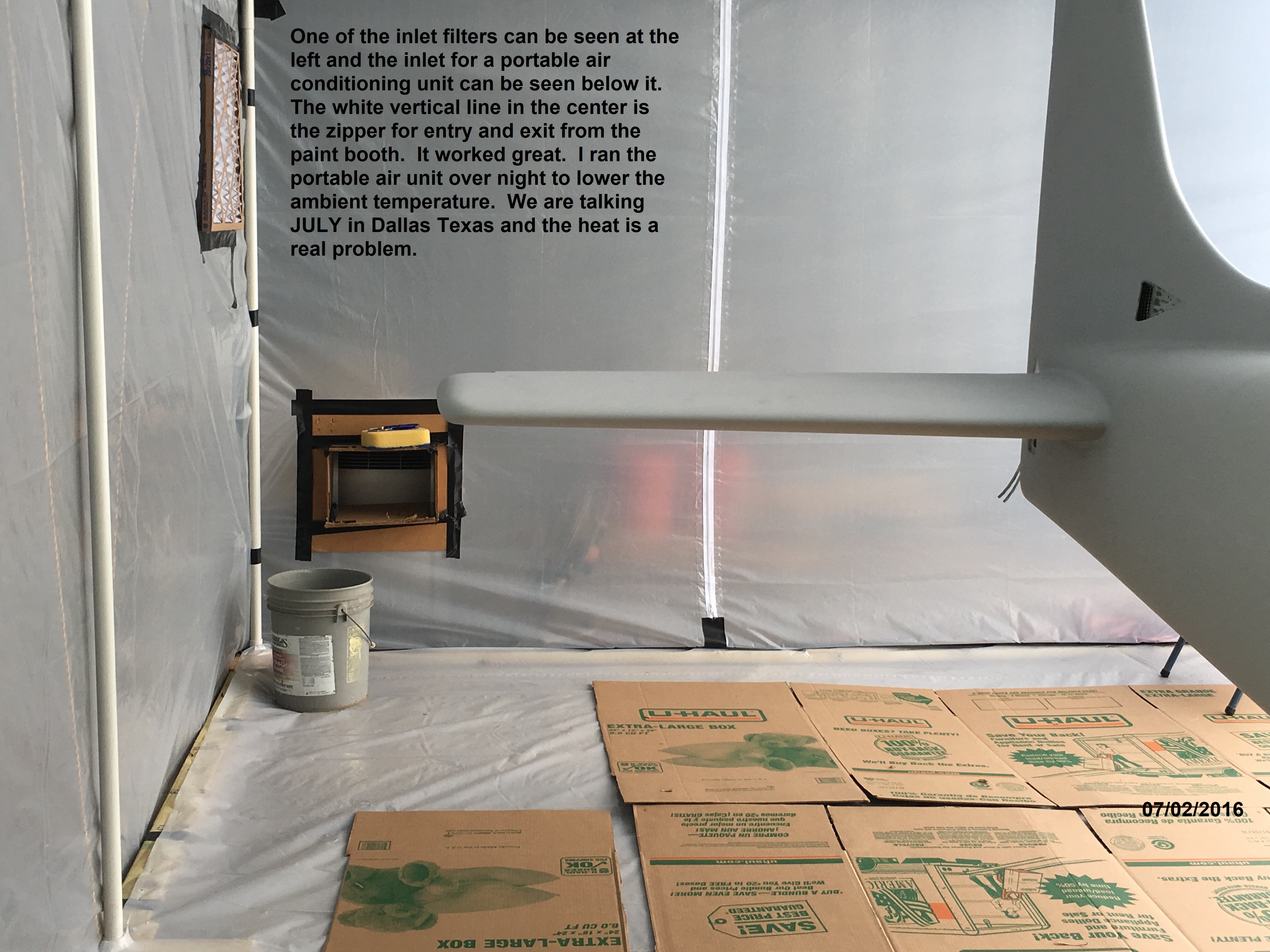

I

placed inlet openings with filters on one side of the paint booth and

exhaust fans on the outside side to pull the paint overspray and fumes

out. I used some cheap box fans with filters taped to the inside

of the fans. Started with two inlet filters and two exhaust fans

but that wasn't enough and the filters I used would clog up too quickly.

|

|

In

addition to the inlet filters and the exhaust fans, I had bought a

portable air conditioner that I used to lower the air temperature

inside the paint booth. I started the air the night before and by

the next morning the temperature was down to an acceptable level for

painting. (It was SUMMER in Dallas and without the air unit, the

temperature would have never gotton below 85-90 degrees.)

|

|

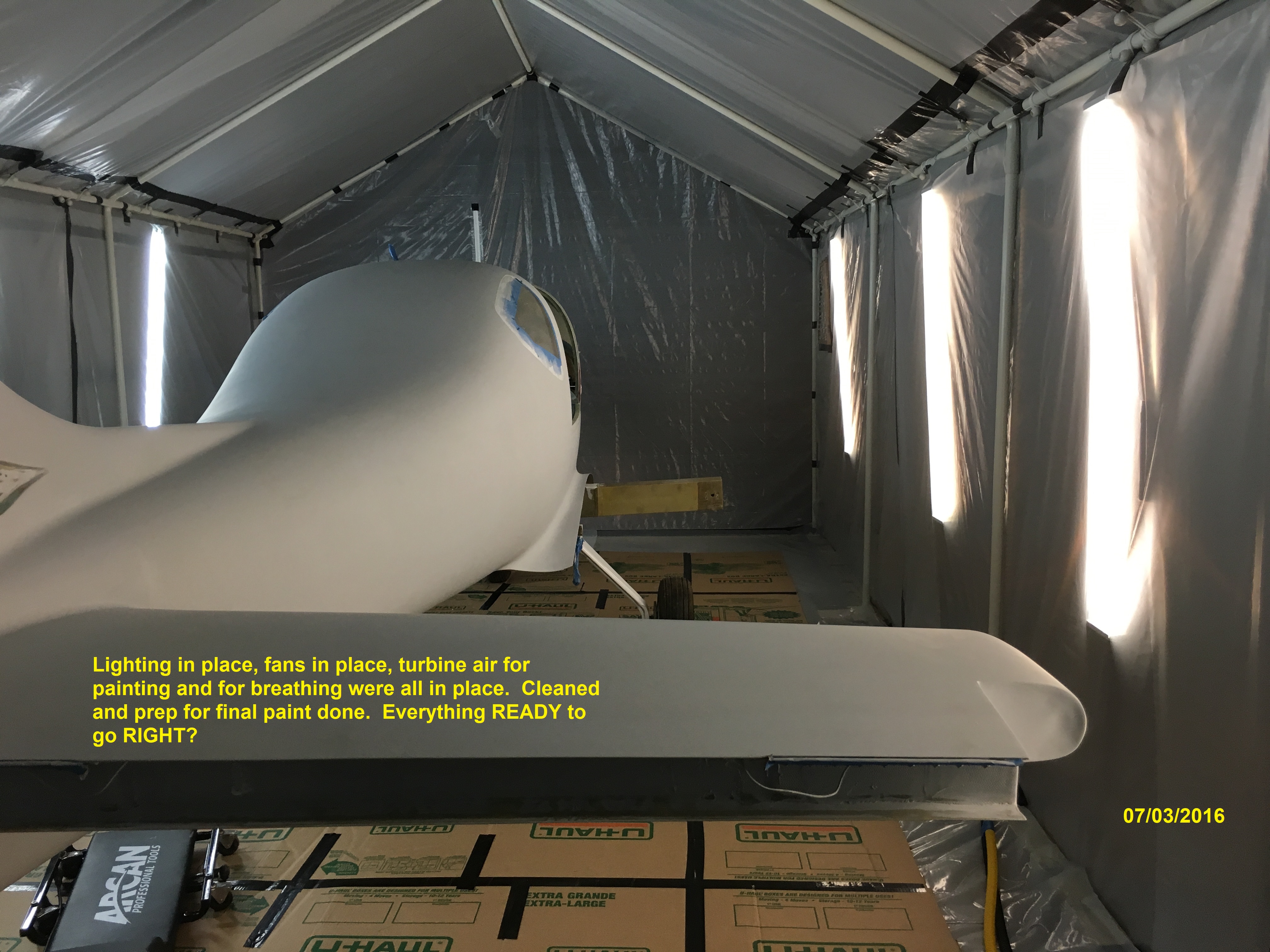

The

filters have been taped to the fans and all of the lights installed

on both sides of the paint booth. Everything is about ready for

for

starting the painting or at least I thought they were. Next was

to

tape and cover everything that I didn't want paint on, final sanding,

and a solvent wipedown. |

|

The

lighting wasn't perfect but it was good enough except they drew power

that we didn't have to spare.

|

|

Now

doesn't that look like the perfect setup of all time? It was

summer and the turbine units had a tendancy to get hot after a few

minutes use and that wasn't great for painting in a hot

environment. The styrofoam box is filled with ice and water with

the air hoses looped around several times under the ice. It

worked up to a point but the whole thing was way too much for the power

available in the hangar. The only elecrical power in the hangar

is one double plug attached to a 20 amp breaker over 200 feet away at

the end of the hangars. I could get both of the turbine units

running but they never got up to full capacity. As soon as I

turned on the lights the power dropped off even more and after about

5-10 minutes it tripped the circuit.

|

| The breaker was at

the far end of the hangar, outside of a fence that

requied me to drive a half mile to get out of the airport and get

access to the breakers. Did a reset and tried again with some of

the lights turned out. Didn't make any difference, between the

lights, fans, and air units there was just too much of a draw to get

good paint coverage. |

|

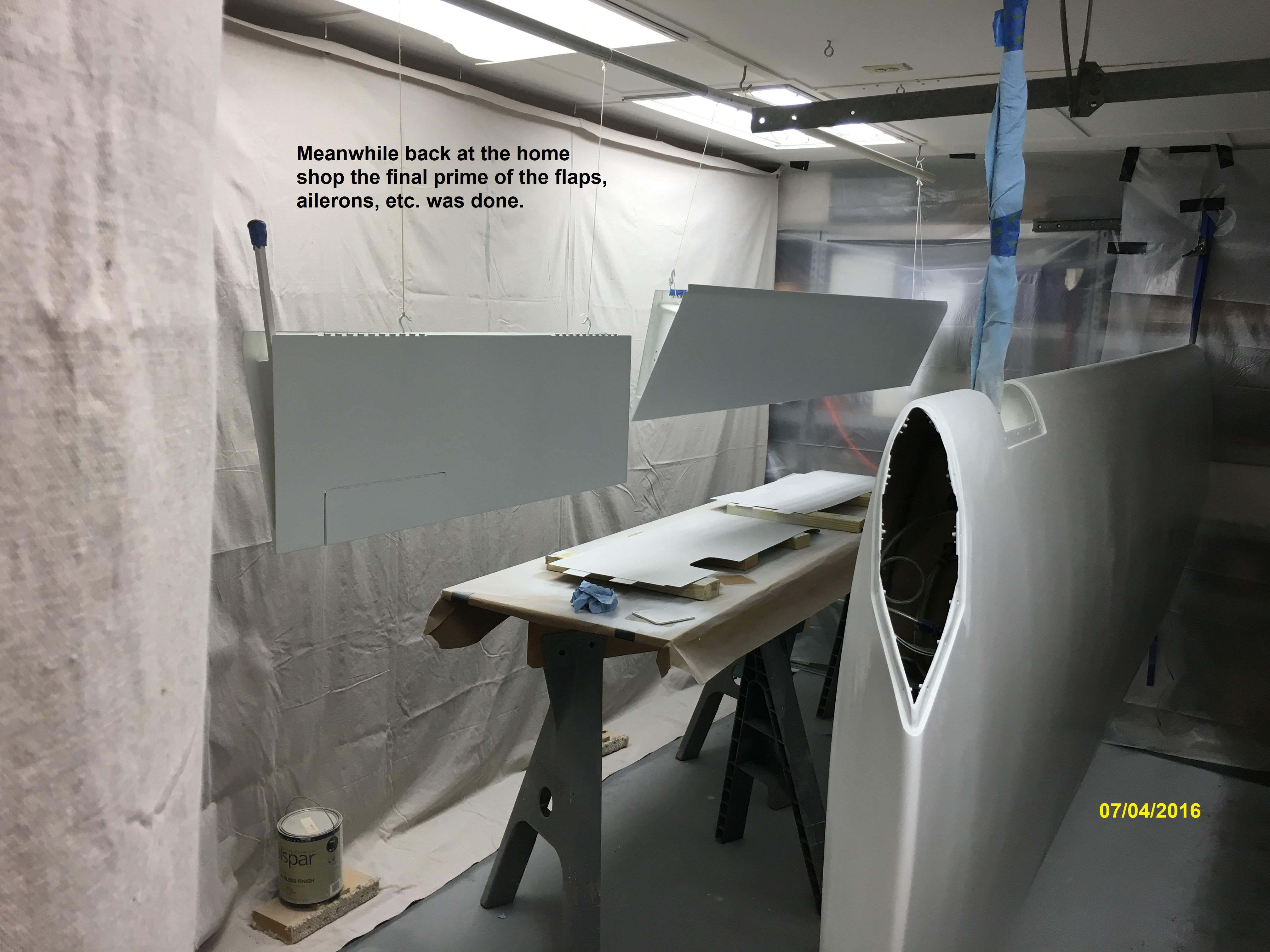

I

had better luck at home with the primer coverage but that was the only

place I could use the turbine unit. Too bad, it worked great when

it had the needed power supply.

|

|

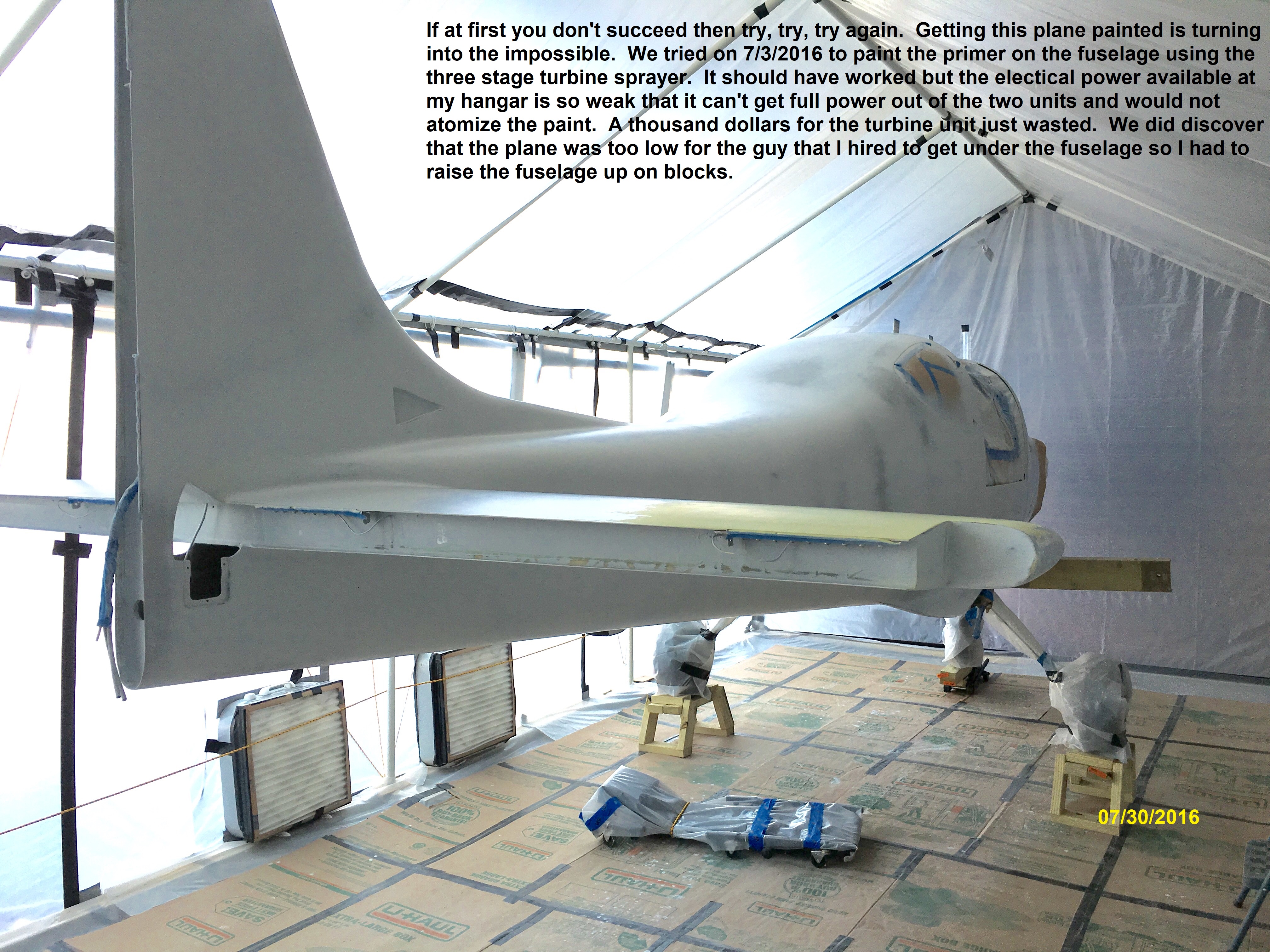

Well, we tried with the turbine units and

once again

failure was an option. We did learn a few things beyond the lack

of power from the first attempt. We learned that the fuselage

needed to be elevated to allow may paint man to get under the plane to

paint. He is a big, tall dude and even with the creeper, it was

impossible for him to move around under the plane thus the need to put

the plane up on stands. This did work much better but then

required a stool to get to the top.

|