Painting this plane has been one disaster

after another and it seems

that nothing was going to work. There weren't any options other

than trying to do the painting myself since there is no paint shop on

the field. The only operations on the field with any painting

capability will not do painting for anyone or allow anyone to use their

facilities. Moving the plane to any other field wan't really an

option either. So, after several other attempts including using a

roll and tip painting method used for boat painting and application of

a vinyl overlay this was my final attempt to get the plane painted.

|

|

After several attempts to get a

full paint job on my plane I finally resorted to building my own paint

booth and going with a traditional spray paint process. There

were no other painting facilities available at the Lancaster Tx.

airport and I had avoided the idea since my hangar is an open T-Hangar

and I was worried about possible overspray drifting to other

bays. I found a steel garage assembly for just a few hundred

dollars. The basic kit was for a 12 x 21 ft structure. I

ordered an additional section which brought the completed assembly to

12 x 28 ft. Enough to hold the fuselage and still give room to

more around the plane.

|

|

I did a full pre-assembly of the

paint booth in my driveway at home where I could put everything

together and build the bottom support plates needed. I also cut

and fit all of the plastic panels that would be needed for the top,

ends, and sides. All of the panels were fit to the structure,

taped with duct tape and added tie rings for holding the top and sides

flight. The idea was to have everything fully tested and ready

for an easy assembly at the hangar without any additional

fabrications. To that end, it was 95% on target.

|

|

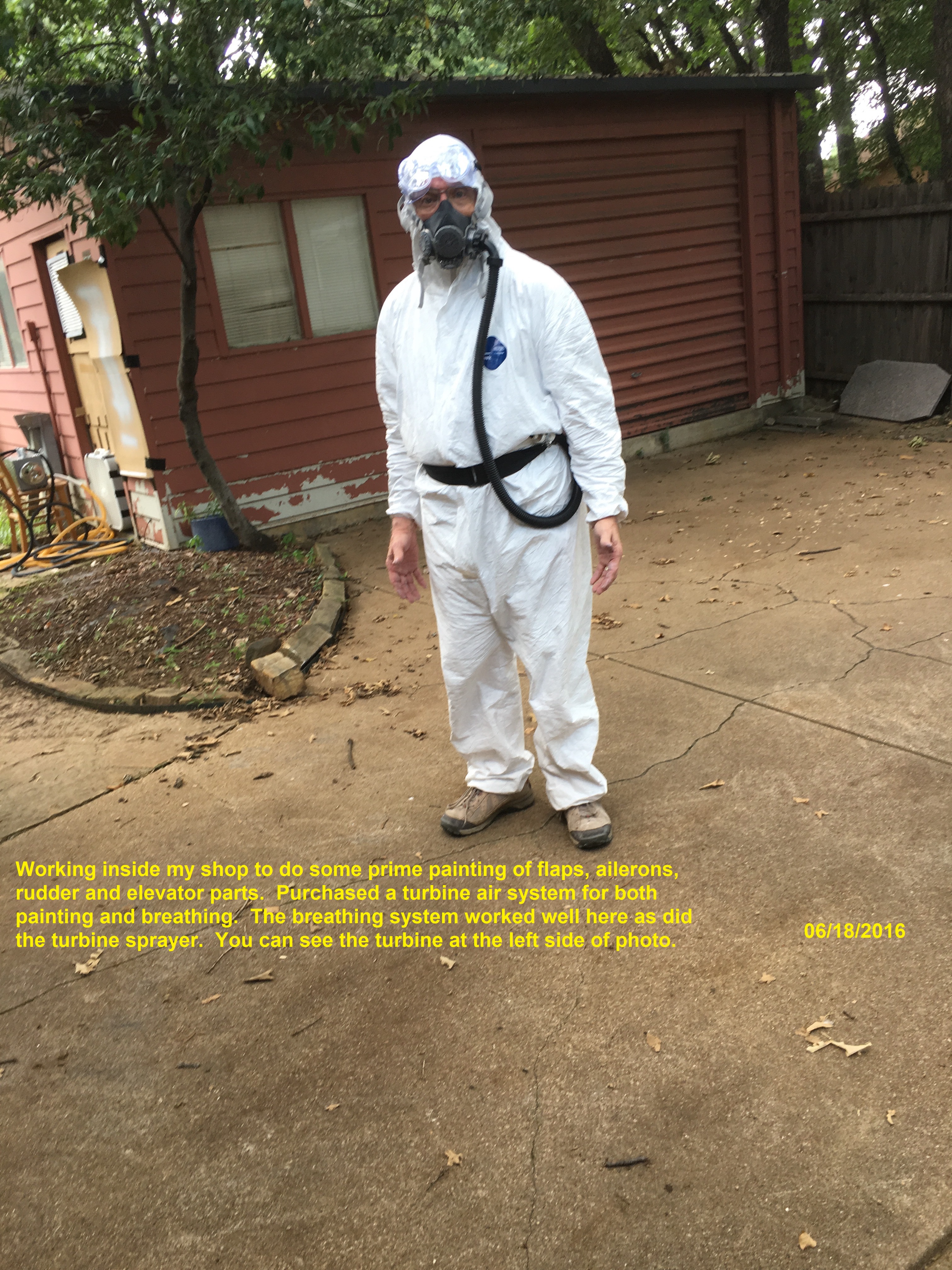

Along with the paint booth I

purchased a three stage turbine air spray paint system and a turbine

breathing air system. Between February and June I used the

turbine units to do some of the primer work using the System 3 Water

Based Primer and epoxy paint.

One thing I would change if I

ever have to work with a spray system

again is to get the fresh air hood instead of the mask. The

problem one encounters with the mask and goggles is overspray on the

goggles and fog from your breath on the goggles. The fresh air

hood would eliminate that for the most part. Also, I would try to

put some fresh air into the overalls.

One of the turbine units can be

seen just outside of the door on the

left side of the workshop. The turbine unit worked great in my

shop and some work I did outside of my garage. It put out a very

uniform and easily controlable pattern. I wish I could say the

same thing when I tried to use it at the hangar. I can't blame

the turbine unit though, it has to have a good source of power and that

is NOT available at the hangar.

|

|

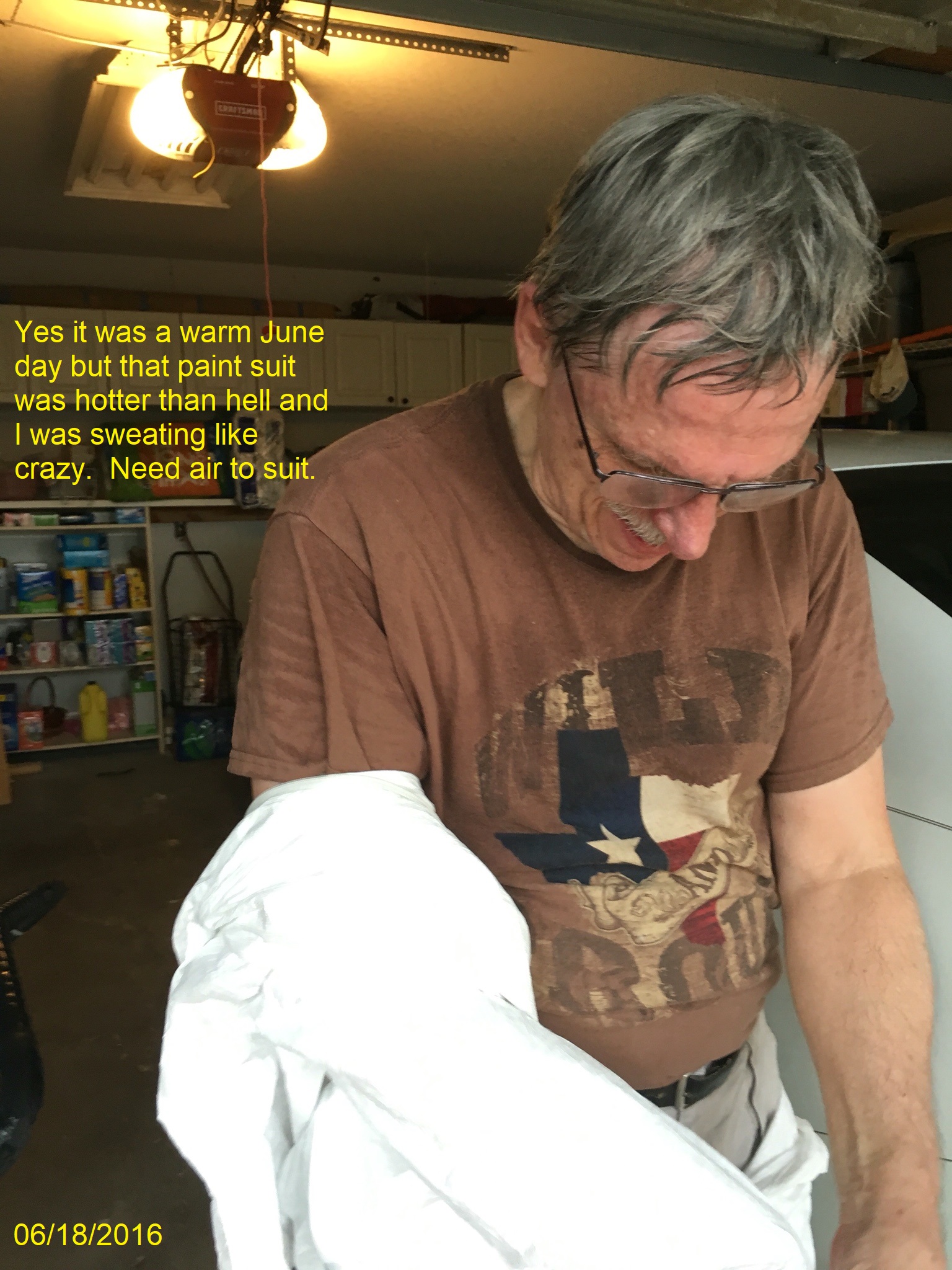

These overalls are great for

protection from the overspray and the fresh air system is a

lifesaver. However, in the summer heat of Dallas the overalls are

nothing short of a sauna chamber and withing a few minutes of putting

it on, you will be pouring sweat.

A better alternative would be a

full body suit and hood with the fresh

air going into the back of a hood and then feeding down into the rest

of the suit.

|

|

My hair was soaked as were my

clothes. I couldn't wait to get out of that thing. It

serves the purpose intended but you will pay a price.

|

|

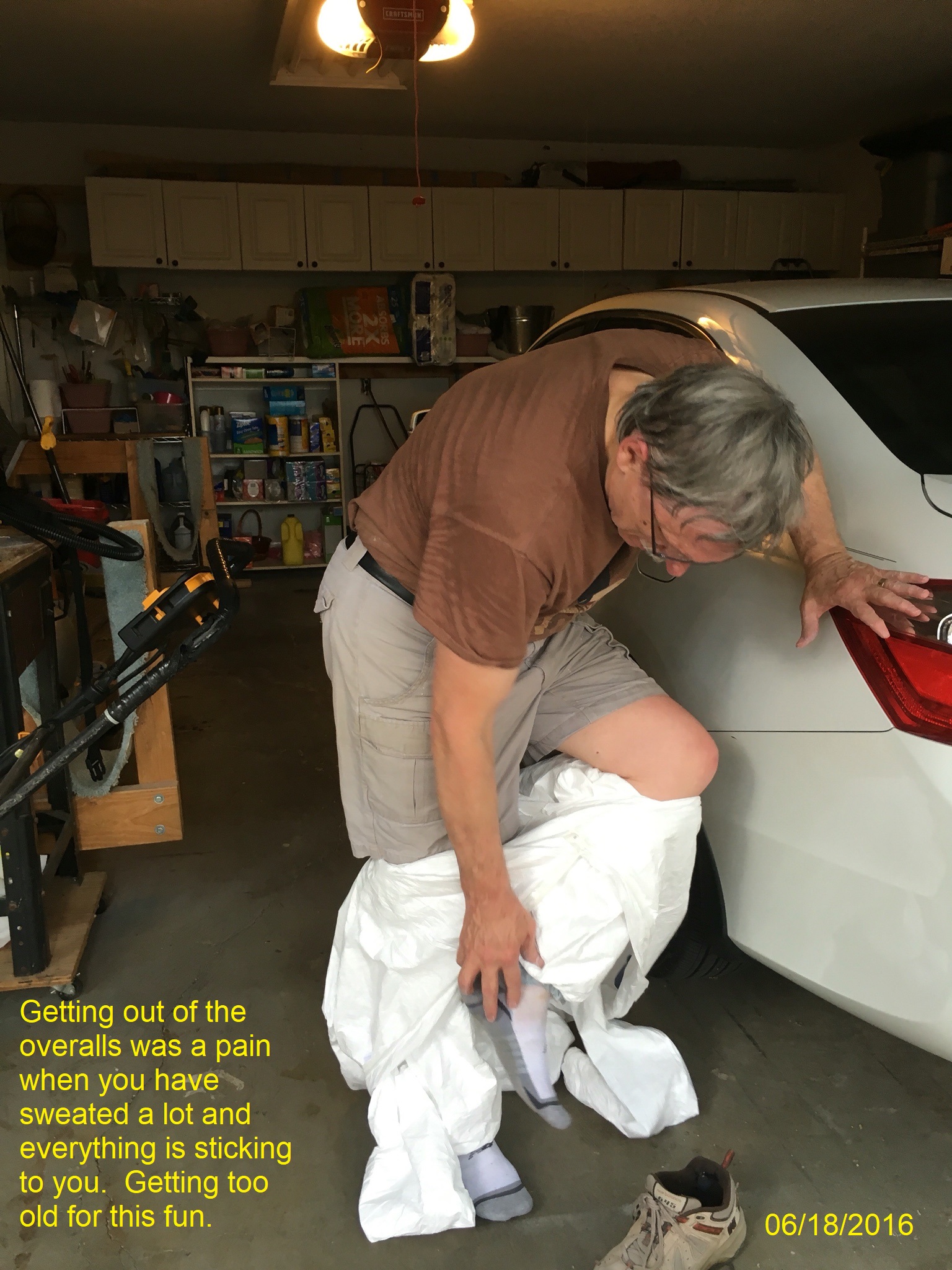

Still trying to get out of that

suit and my wife was having fun watching me struggle to get out of

it. It was sticking to me because of the sweat. I was not

singing any praises at this point.

|

|

Finally

moved all of the paint

booth and supplies to the hangar to begin the assembly process and the

finish coat process.

|

|

Working on

this process alone was interesting but having already done a

pre-assembly at home the process was straight forward. The

eprocess

was slightly different since the unit had to be assembled as two

separate units. The fuselage had to be move out of the hangar and

one

end of the paint booth assembled. The fuselage was then moved

into

that secton as far forward as possible. |

|

The second half of the structure

was assembled behind the plane and then the section was slid into place

and joined to the front section. There wasn't that much room at both

ends of the fuselage and the top section had to be assembled then

raised with the side poles one side at a time.

Once the framework is up, the

side curtains will be installed and the seams sealed with tape.

|

|

The

completed paint booth is 12

feet wide and 28 feet long. That gave good clearance around the

sides and back of the fuselage for painting.

The fuselage has already been primed using the System 3 primer and

sanded but needs one more coat of primer before the final color

coats. This primer had been on too long and needed to be

refreshed.

|

Continued on the Next Page

|

|