|

Using an open cell foam I obtained from a local hobby

supply store, I cut the blocks at the same angle of the gear attachment

to the underside if the aircraft. I glued blocks together as

shown on the left. I then cut slots in the foam and fit them

under the fuselage and around the upper portion of the landing gear.

|

|

Once the fit around the gear is obtained, the rest is just

a matter of sanding the blocks to the desired shape.

Sanding the foam is no problem but keeping it from disentegrating

at the edges and not breaking it as it gets thin can be a bit

interesting. The next step is to cover these with glass. |

|

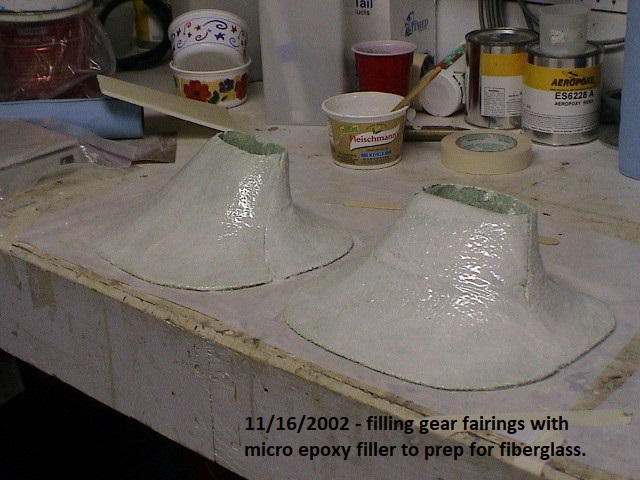

The first step to laying glass over the form is to fill

the open cells of the foam with a micro-epoxy mix. I let the mix

cure, sanded the form with 60 grit paper and prepared it for the glass

covering. |

|

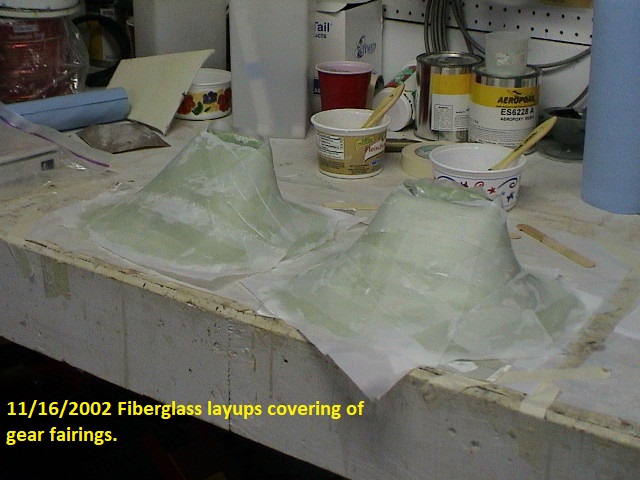

The glass was layed up in multiple small overlaping bids.

This made it much easier to follow the forms. After

application of the bid, strips of peel ply were added to hold the glass

in place and make the finished product smooth and require less sanding

to finish. |

| The end result came out looking pretty good

but still not quite what I wanted. I have done some additional

sanding and filling to get the shape perfect. Once everything is

right, I will add another think layer of glass to ensure the ultimate

strength. |

|

|

|

|

|

|

A

fiberglass panel is required to cover the underside of the landing gear

crossover. I used a standard prepreg panel and trimmed part of

the lower side to produce a mounting lip.

|

I then applied fiberglass layups to the inside of the cover to reenforce the mounting lip.

|

N247BR

N247BR N247BR

N247BR