| I wonder....is there some significance to the fact that we start

most

airplane projects with the TAIL?

The KIS Cruiser Kit, like many other homebuilt aircraft kits,

can be started

with the horizontal stabilizer and elevator kit. Often this

portion

of the kit can be purchased separately and used as a test kit to

determine

if you are really interested in, and have what it takes to build an

airplane.

It also provides an opportunity to see if you are going to feel

comfortable

with the construction techniques.

The KIS Kit can be purchased in that manner if you choose to

start that

way.

I had decided to purchase my kit in two parts, a fuselage kit and

a wing

kit. The horizontal stabilizer and elevator were part of the

fuselage

kit but I had them shipped early since it was going to take a couple of

additional months to prepare the fuselage kit. I just couldn't

wait

three months to get started once I had finally decided to do it.

|

|

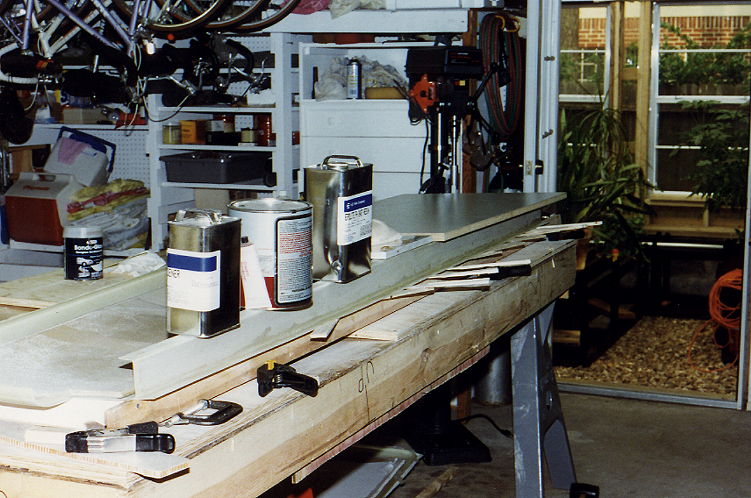

The Tail Kit contains two premolded fiberglass pieces

which form the top and bottom of the horizontal stabilizer and the

elevators. A long "U" shaped molded fiberglass piece forms the

rear spar of the stabilizer. A flat prepreg fiberglass panel is

also included. The outline for the ribs and elevator spar are

drawn on this panel. Included also are a supply of fiberglass

cloth, epoxy resin, hardware, and Hycell Glue required for completion

of the assembly. |

|

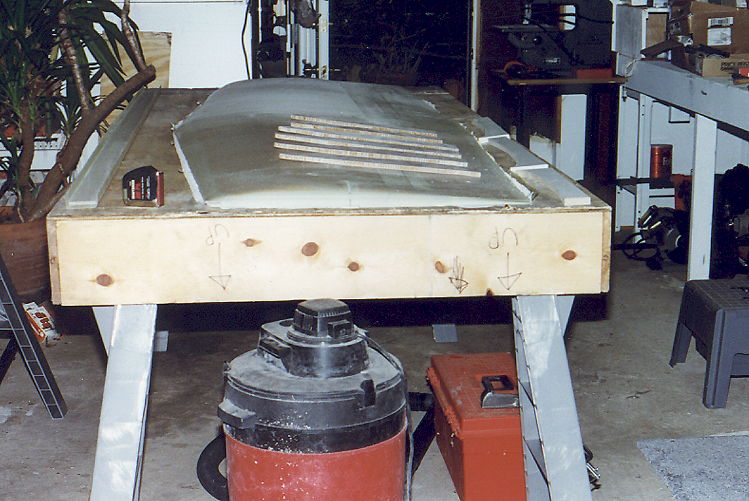

The first steps involve preparation of a work surface to

hold the stabilizer during the subsequent operations. Patterns

are provided for braces to support the stabilizer on the work table.

A cross brace supports the spar edge during assembly.

(NOTE! Use a totally straight edged hardwood board for this

piece to avoid any warpage. This is not specified in the manual

but is very important. I did not and there was a slight warpage

in mine which transferred to the completed part.) |

|

|

|

Next step involves locating scribe lines on

the molded parts for separating the elevator panels from the horizontal

stabilizer. The scribe lines are etched lines in the molded parts

and are just barely visible. A sharp pencil run along the lines

helps to make them show up. The elevator is separated by

carefully cutting along the scribe lines. This cut is very

important and must be done with a smooth straight cut for proper final

fit. The manual indicated that some possible problems in the area

of the elevator counter weights. I second that and add my own

caution. I carefully cut according to the lines and found that

the side edges on the stabilizer did not align by almost 1/2 inch.

I recommend double checking the position of the lines on both the

top and bottom. |

|

|

|

|

|

Once separated, the top of the stabilizer is mounted on the work area

and the rear spar positioned and bonded into place. |

|

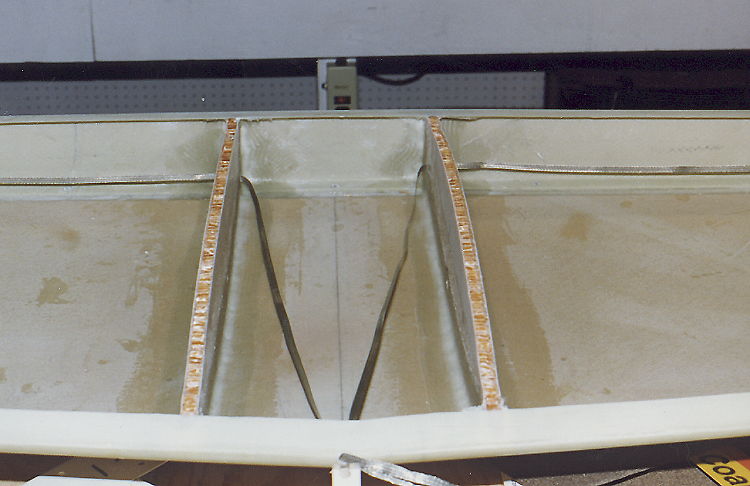

The ribs, which are cut from flat prepreg panels, are

then positioned, checked for proper fit, and glassed into place. |

|

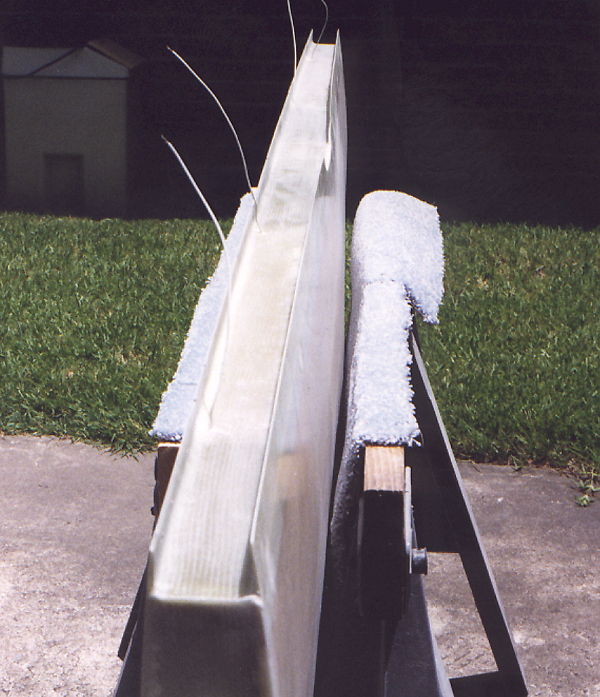

Once all the ribs are glassed in place, they are trimmed to fit with

the bottom panel. This shows the ribs prepared to receive the epoxy/flox

mix for joining to the bottom stabilizer panel. Shown also are the

electrical bonding ground wire which I chose to include. This is part

of a bonding wired that links all metal parts of the airplane. |

|

|

|

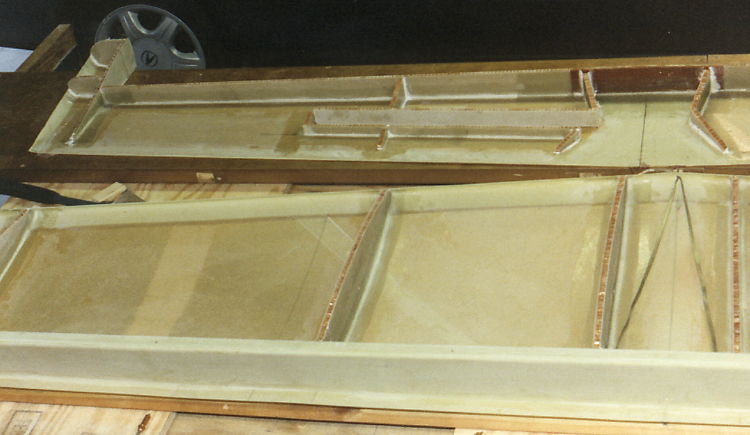

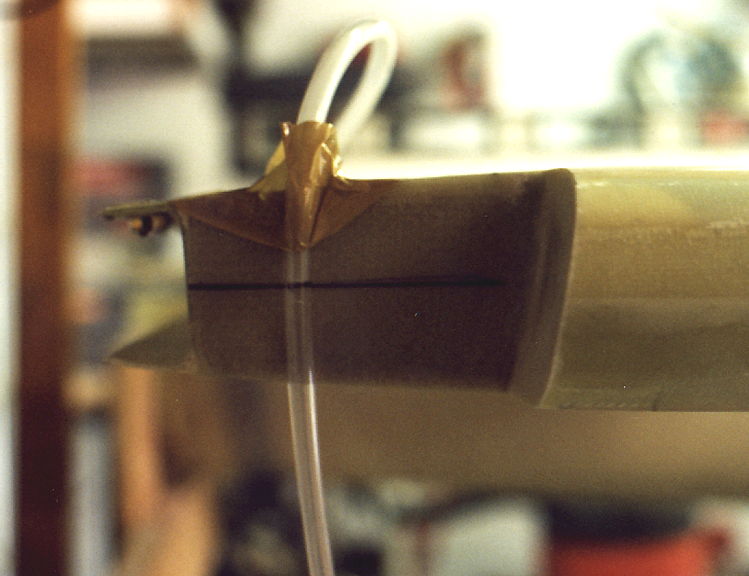

The above photos and left show the horizontal and vertical stabilizer

both ready for closeout. |

|

The stabilizer has been finished, the front edge and spar have been

covered with Hycell Glue, and the ribs have and epoxy / fox fillet for bonding

to the bottom panel. Everything is ready for final closing of the

Horizontal Stabilizer. |

|

The above is a close up of the epoxy / flox fillet just prior to close

out. The inside of the bottom panel have been painted with epoxy and

glue spread on the leading edge and spar joints.

|

|

A lot of clecos, some lead, several bundles of shingles and you have

enough weight to close out the stabilizer. |

|

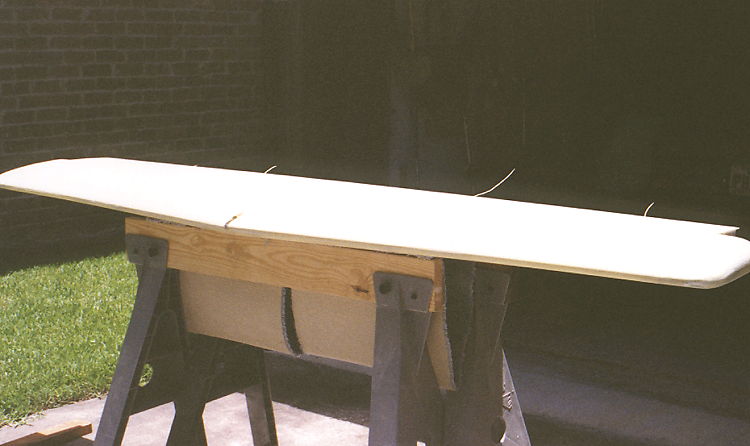

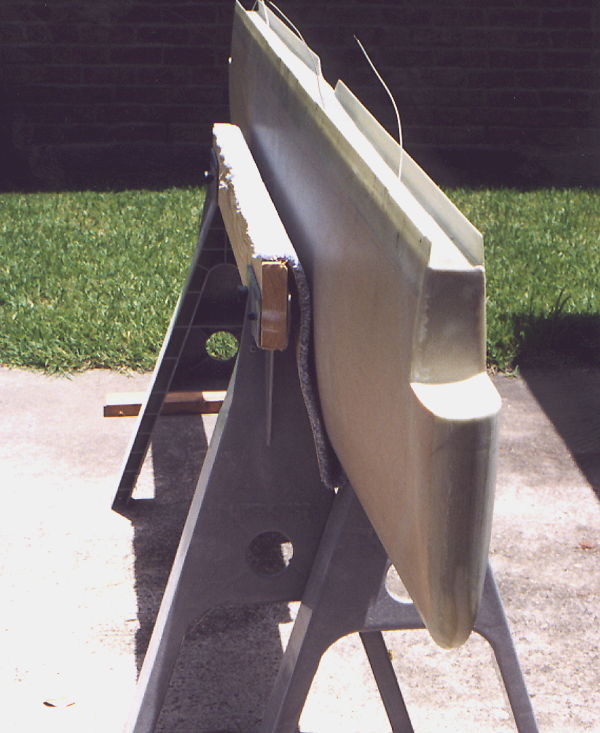

A cheap and handy method of holding the horizontal stabilizer, elevator

and rudder during construction and some finishing operations. Just

a couple of lengths of carpet tacked to the tops of two sawhorses. They

hold the parts and protect them at the same time. |

|

|

| The forward edge of the stabilizer is joined by the overlap of the

upper and lower halves of the molded parts. This forms a very rigid

and rather thick edge. Some filling and sanding are required to produce

a clean smooth edge. |

After closing the stabilizer, the inside of the spar area are glassed

and additional glass added for the hinge mounting areas. The counter

balance area is filled and glassed. Two ply fiberglass bids are then

applied to the ends to finish out the stabilizer and it's just about ready

for installation. |

|

|

| This above shows the arc shape I formed to allow for closer tolerance

between the elevator counter weight and the stabilizer. This provides

for about a 1/4 inch gap that is consistent through the entire movement

cycle. |

|

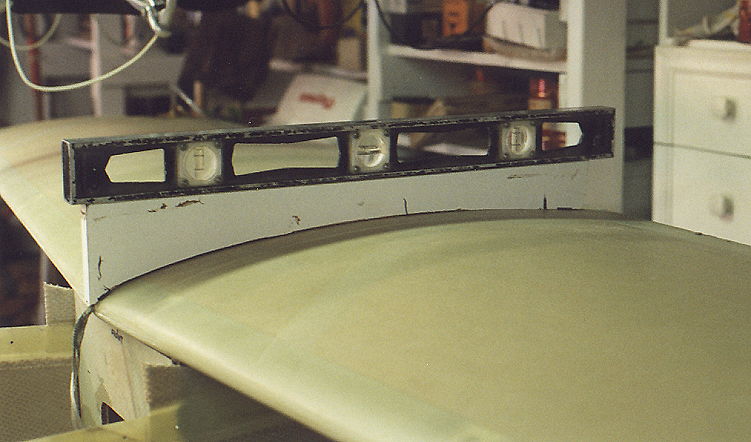

Installation

of the horizontal stabilizer starts with making a template for leveling

the horizontal stabilizer. The fuselage must be leveled side to

side and front to back before mounting the horizontal stabilizer.

A bulkhead is place under the front of the stabilizer and the fuselage

tub is cut to the shape of the bottom of the stabilizer. Once

everything is set, a side to side level operatoin is made to ensure the

position is exact.

|

|

The sides

of the fuselage under the horizontal stabilizer are adjusted until the

horizontal stabilizer is perfectly level from side to side. A

water level was used to perform this operation.

Once the horizontal stabilizer is accurately positioned a flox bead is

run underneath the horizontal stabilizer and glass bids applied to the

underside of the stabilizer to join to the fuselage.

|

|

In

addition to making sure the horizontal stabilizer is level from side to

side, position accurately from front to back and level, it must also be

positioned exactly the same distance from the front firewall station on

both sides. This was a very time consuming process that required

checking, checking again, adjusting, and checking all of the

measurements again. The bonding process had to be done carefully

to keep the horisontal stabilizer from moving while the bonding

operation was being completed.

(No I was not expecting at the time but I did lose some weight after seeing that photo.)

|

|

The

completed and painted horizontal stabilizer with the elevator installed

can be seen in this photo. The hinge screws have been recessed

and covered with glass to produce a very clean surface between the

stabilizer and the elevator.

|

|

The front view of the stabilizer shows a clean smooth transition between the stabilizer and the fuselage.

|