|

|

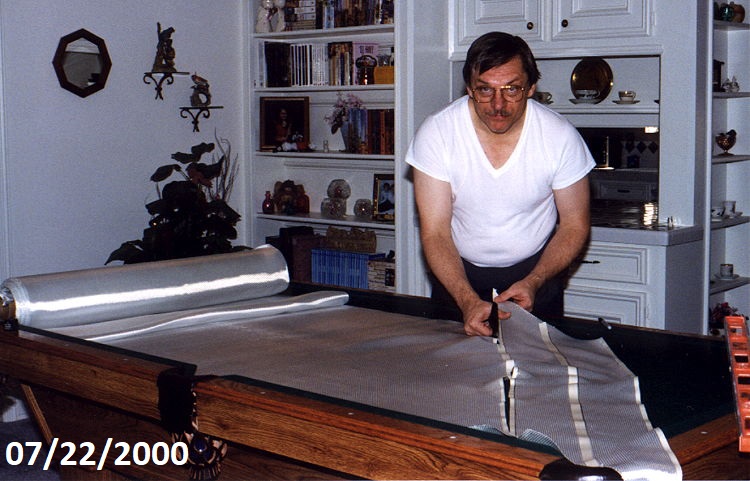

| It's a bit difficult to see but I mark a line on the glass

and then use 3/4 inch masking tape to bind the glass along the line. |

I then cut the tape in half during the cutting

operation. The tape is left on and cut off after the glass is wet

with epoxy. |

|

My cutting table is a pool table in my den. It is

really a nice way to layout the glass since it is easy to smooth the

glass and maintain a good clean working environment. It is also

very easy to work on cutting glass in any kind of weather.

|

| I have used the table for making my patterns and cutting

the glass in bulk. I match the pattern to the glass, weigh it for

determining the epoxy required and store them in large ziplock

bags for future use. It does cause some problem with the bank

shots however. |

|

|

|

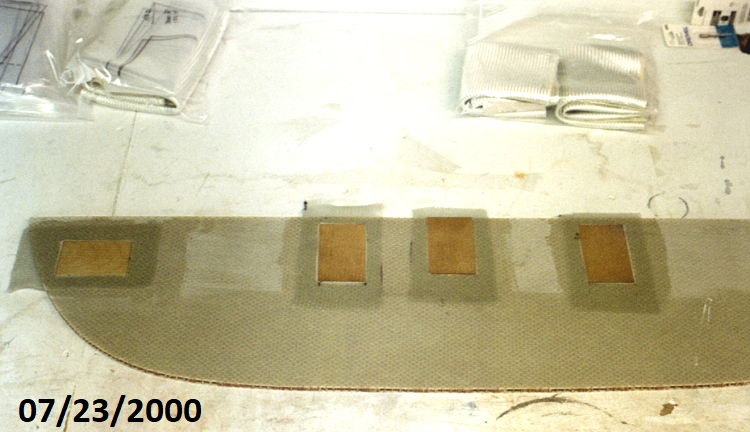

| Here you see several packages containing both patterns and

pre-cut glass needed for layups for installing the firewall and rear

spar. |

This and the photo at the left also show the hard points

required for the station 30. One of the few benefits of not

getting the quick build option. |

N247BR

N247BR

N247BR

N247BR