| There are a

couple of real advantages to the quick build kit. Namely

the installation of the firewall, the main bulkheads along with the

main

and rear spars. The disadvantages are that you then must work

around

these preinstalled componets to install hard points for controls and

seatbelts.

You are also required to cut out the front and rear seat backs

from

the preinstalled parts. The advantage to not getting the quick

build

are being able to install many of the hardpoints on the work bench

before

installing in the lower fuselage. I am not sure how much time

difference

there is but it sure is a lot easier on the back. |

|

|

|

|

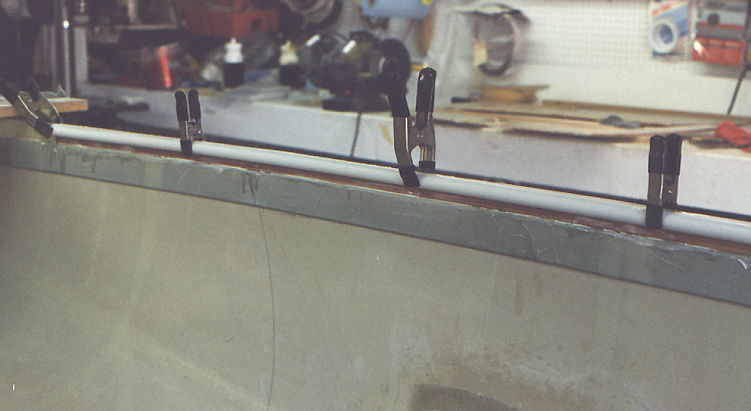

| Initial start of bonding

of the rear spar. The 1 x 2 is an oak spacer used to keep the

fuselage at the correct width until interior bulkheads are installed. |

This shows the lower portion of the rear seat back

being fit for installation. I installed all hard points for the

rear seat belts before installing the seat back. Saves a lot of

time. |

|

|

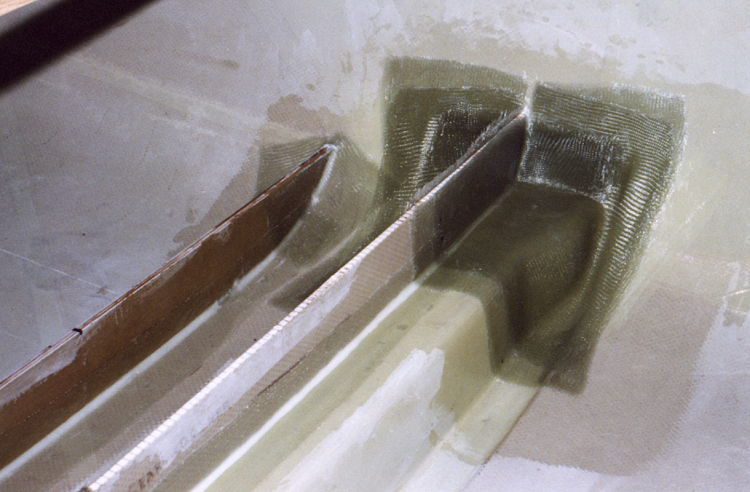

| Here is one view of the

layups for the rear spar and the stiffner for the landing gear recess. |

A view from the other side showing the rear spar and gear re-enforcement.

|

|

|

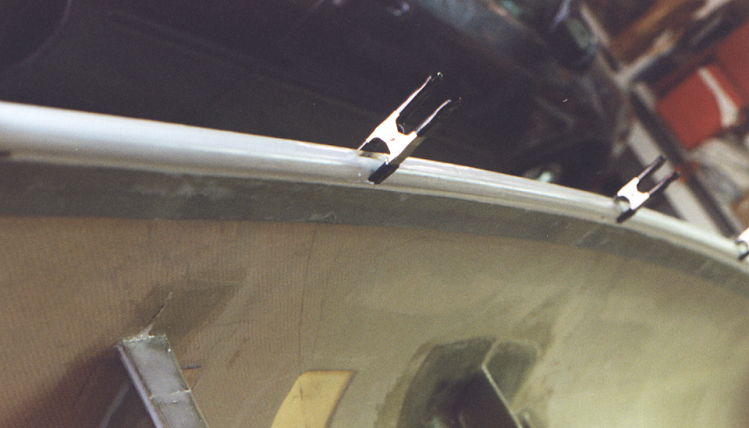

| A shaped length of 1/4 inch

plywood has been bonded above the longeron. The PVC conduit is

being bonded on above that. |

A micro filler has been used

to fill the gap between the sides and the PVC conduit. Micro Filler is

also used to fill and level below the PVC. |

|

|

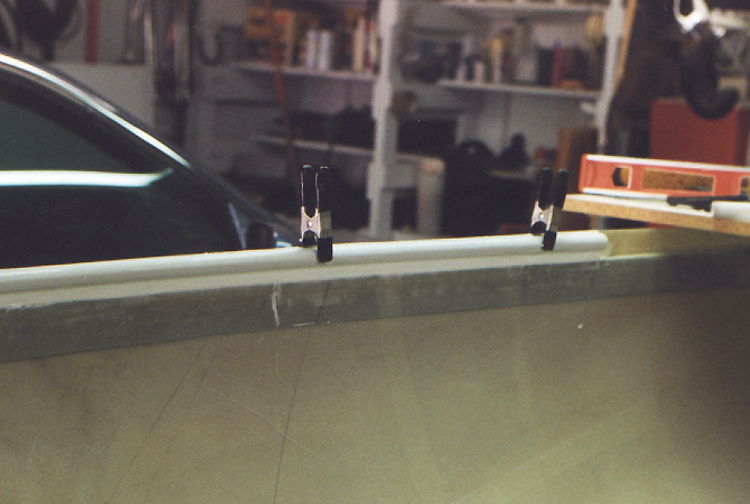

| This shows the conduit in

place and ready to add the two plys of glass to complete the conduit

and add strength to the fuselage sides. |

A total waste of film and

paper but required from time to time just to prove that I am me and I

am the builder. |