|

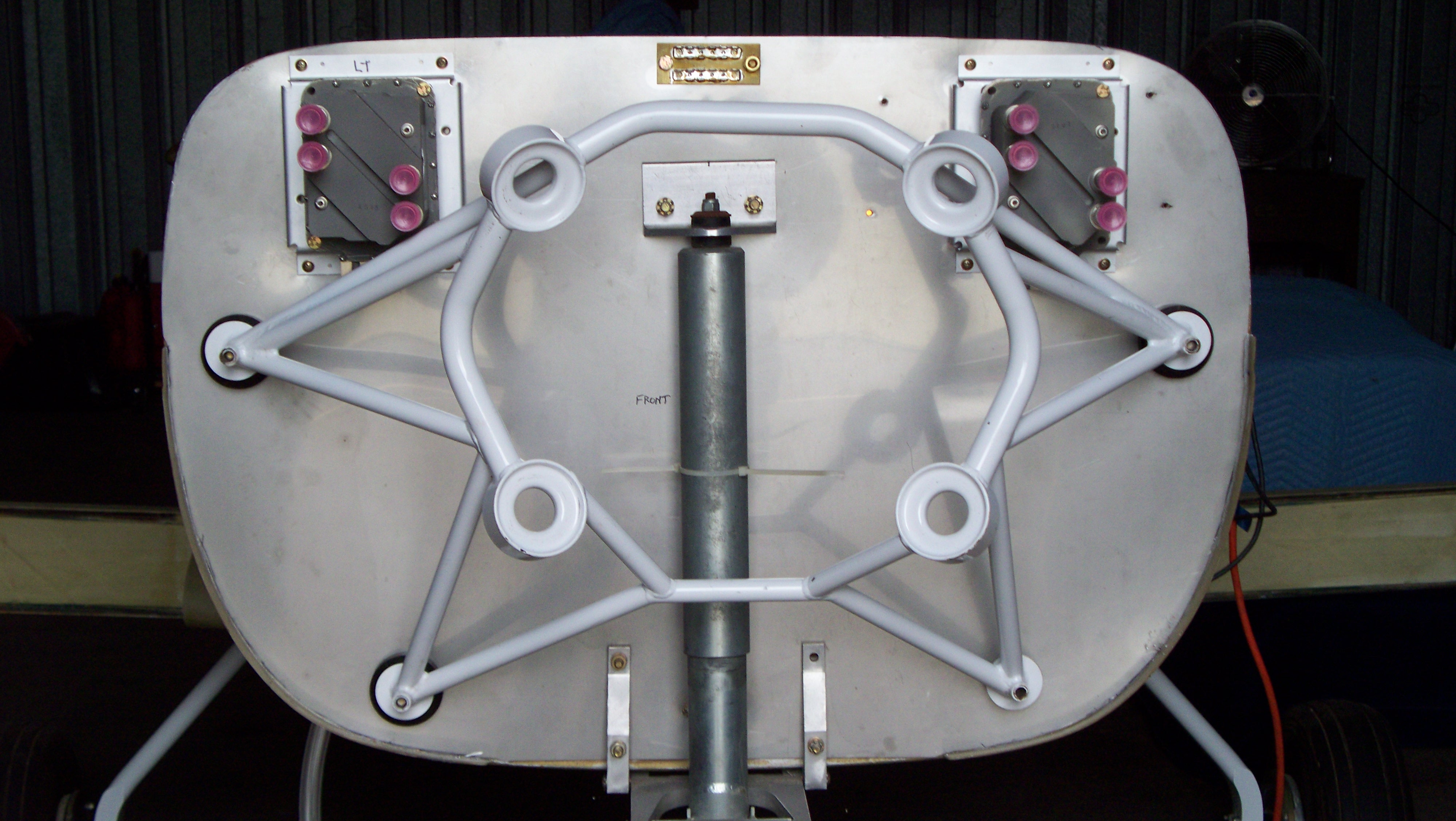

| A nice CLEAN Firewall with nothing to clutter up the

smooth clean surface. Now the fun begins. |

|

First things first. The FADEC system electronic spark

controls are required to be placed within a certain area on

either side of the center line. Problem number one, the engine

mount covered almost every possible location for

the sending units. The black rings around the pads on the engine

mount are temporary 1" spacers needed to move

the engine mount forward one inch. This not only opened up just

enough space to mount the sending units, it will

give needed space for the rear of the engine and accessories. |

|

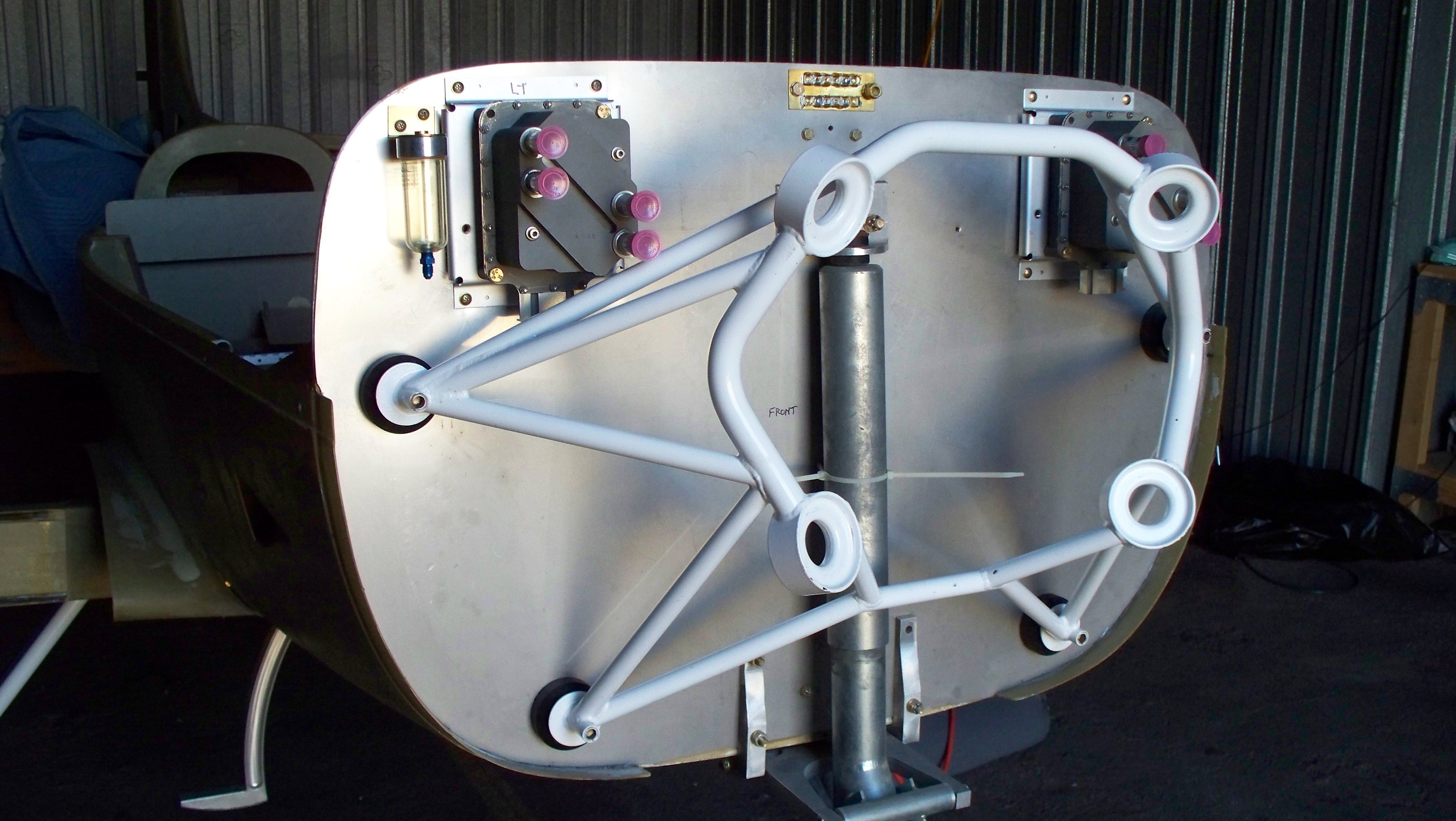

Nothing really mounted yet but its already starting to look

like a lot of fun. The power ground and the brake fluid

reservoir have been added in the most out of the way positions I could

find. Drilling holes through that Stainless

is sure fun and can destroy a drill bit in no time at all. |

|

Is it an art...or a science? Trying to locate

everything on the firewall to give both access and safety for routing

controls, fuel lines and oil lines is more of a trial and error than

art or science. I picked the lowest and closest

point for the GasColator. The ugly black marks show the plan for

routing the fuel line. This position will give me

a fairly straight shot to the engine fuel pump shown in the upper left.

A flexible hose will be used with a tie off

to the engine mount. The remote oil filter is also in an easily

accessed position just below the engine adaptor. |

|

Finding a good position for the oil cooler that would allow

for good routing of the scat tube supplying the cooling

air was also a trial and error experiment. I hope this position

will work out OK and be clear of all the exhaust

pipes when the oil lines are installed. The plan is to use right

angle fitting that will direct the oil lines directly upward. |

|

The stainless steel firewall has been removed to show the

fiberfax facing. The main reason I included this was to

show the forward mounting of the protective pan under the fuselage to

protect it from the heat of the exhaust

system. I still have about a dozen more holes to make in the

firewall for control cables, battery cable, and electrical

cables. |

|

Before putting the stainless steel firewall back in place I

used a random orbital sander to remove the shine from the

surface. I like this surface treatment instead of the mirror

surface that shows every scratch and finger print. One

thing to note is the three large opening. The top opening is for

a "T" fitting that will supply heat for the windscreen

defroster. The other two openings will be used for the heater

control boxes. (One shown in place.) The placement

of these openings was picked to minimize the amount of scat tubing that

would be required on both the inside and

outside of the firewall. The heater shroud will be on the

co-pilot side. The heater output will be split by a "Y" tube

to the upper defroster input. The second tube will be split to

the two heater controls using another "Y" tube. This

gives the pilot and copilot separate heater inputs. The inputs

are directly behind the rudder pedals and will have

a hood to direct the heated air downward and under the rudder pedal

platform. When the heater controls are closed

the heat will be directed down toward the cowling air exit. |

|

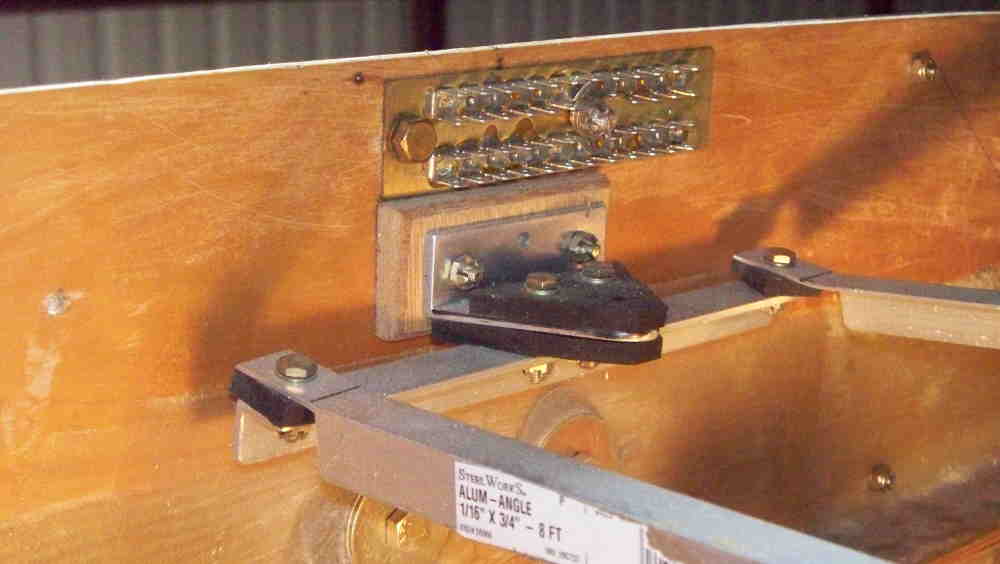

The inside of the firewall is going to be equally crowded but

with slightly different issues. The inside will be very

crowed with wiring and other fixtures. This shows the inside

mounting of the common ground connection. The

bracket shown in this photo is part of the support system for the

instrument panel. The entire instrument panel

will be shock mounted. The bracket shown connects at two points

on the top of the instrument panel. |

|

And I still have another dozen holes to put into the firewall

before it is complete. It already looks like the target

for machine gun practice and there is not a single hole that is not

required. |