|

|

Early

on I decided to use a piano hinge to join the top and bnottom of the

cowling for both an ease of installation and remove as well as the

cleaner look of not having screw or other fasteners running the length

of the cowling. I am very happy with that decision even though

like every other deviation from the plans it cost a lot of hours.

|

|

|

|

|

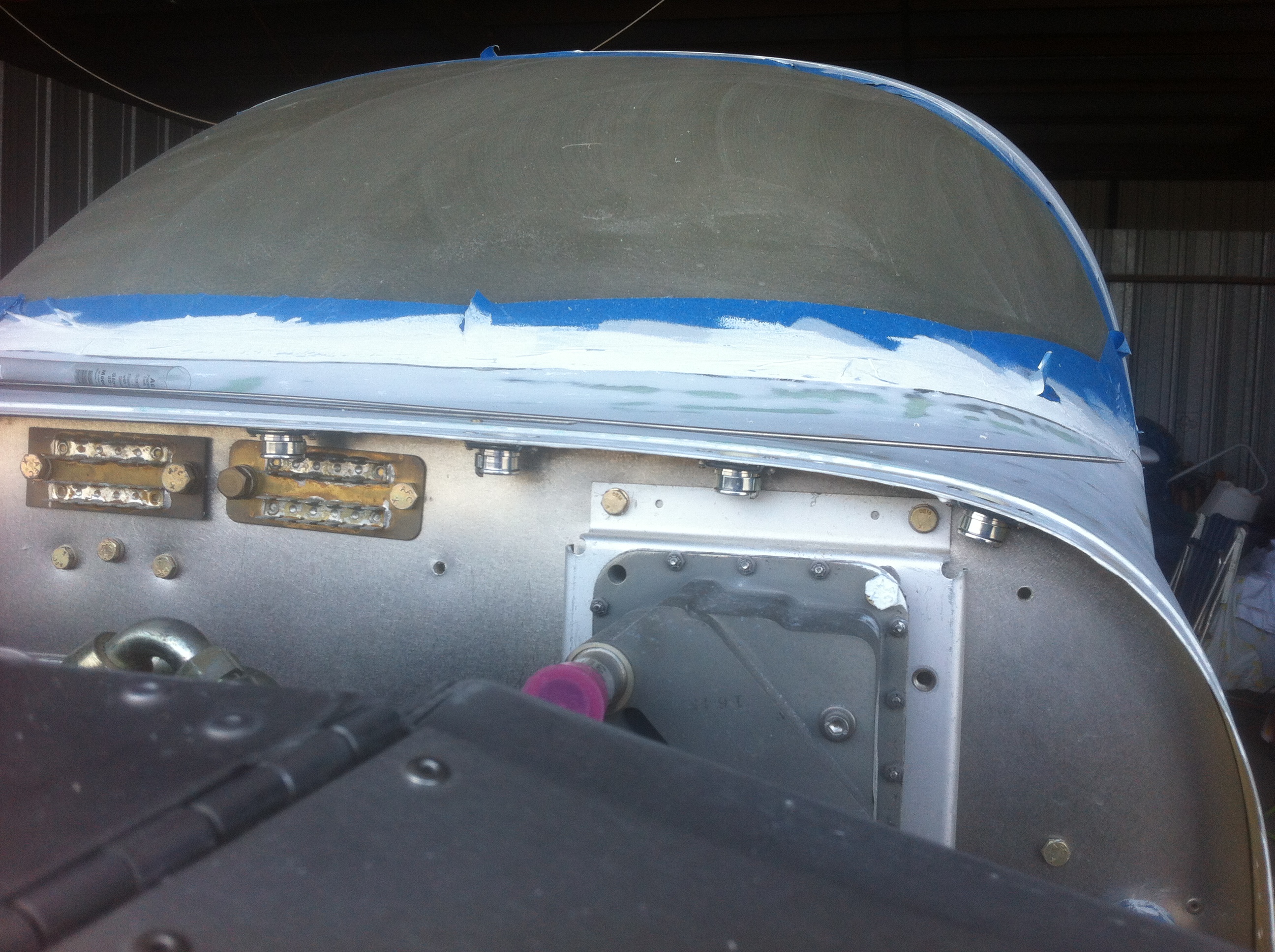

I

used the adjustable cowling fasteners from Aircraft Spruce. The

recepticle is installed in the fuselage and will be adjusted after the

cowling and fuselage have been painted and finished. The

resulting fastner is nearly flush with the surface after installation.

|

|

|

|

|

The

fasteners were only installed across the top and on the sides of the

lower cowling. The hinge pin will also act as a fastner on the

point where the upper and lower cowling meet. What I like the

most about these fasteners is that they are quick connect requiring only

a 1/4 turn to lock in place.

|

|

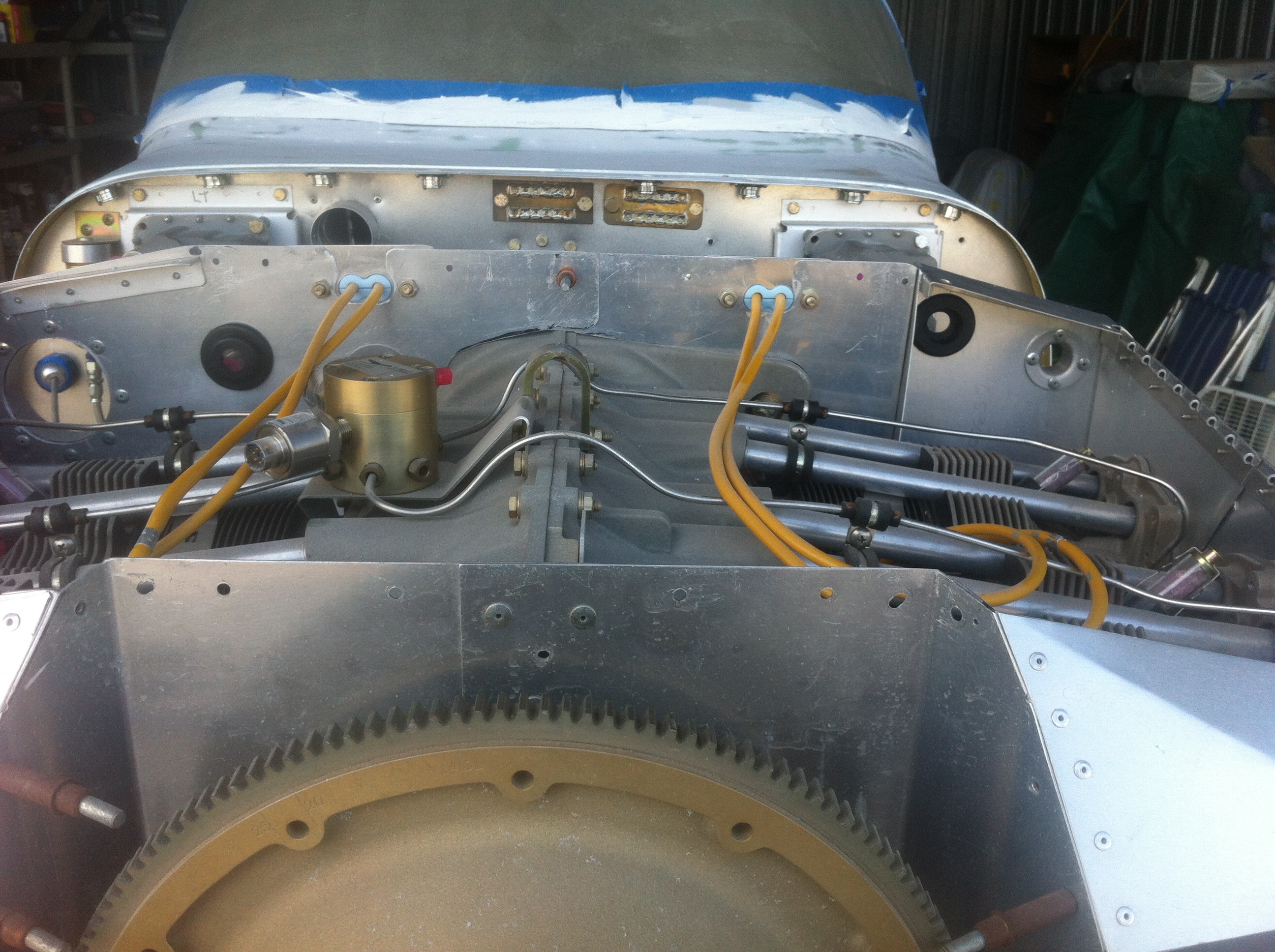

Mounting or removing the cowling will require the prop to

be removed since the three bladed prop doesn't leave enough room to clear the

front of the cowling.

This photo shows the connection to be made between the air box and the cowling

air inlet. The cowling will slide backwards with the inner tube of the

air inlet sliding into the air box inlet. It takes a bit of finesse to

slide it in but it form a good seal and stops the cowling at the proper

place. It provides support for the cowling once installed.

The important part for me was that I can install the cowling by myself.

|

|

|

I

have mounted and dismounted this cowling many times during the

construction process with no problems. I was always able to slide

the piano hinge pin into place without substantial problems. That

was BEFORE painting. I failed to account for the thickness of the

paint causing the gap between the top and bottom of the cowling to

expand to the point that I could not get the thing together.

|

The quarter turn adjustable fasteners turned out to be

both easier and more difficult to adjust than anticipated. More difficult

because somehow some tiny washers or something got down inside the receptacles

and blocked the screw pin from setting correctly. Took me forever to

figure out what was wrong. Once that issue was solved, the actual

adjustments went very smoothly.

|

Fixing the problem with

inserting the hinge pin required sanding the overlap between the

fuselage and cowling to remove some of the paint build up. The

inside of the cowling on the top at the corners up to the first

fasteners had to be ground down to remove some of the thickness.

The lower cowling required some inside grinding to remove the thickness

as well. Finally, the installation process required the lower

cowling to be left loose except for the third fastener from the top on

each side until the pin is installed. Once the pin is installed

the remaining fasteners can be tied down.

Finally, the hinge pin was cut to length and the insert point filed to

a sharp point to ease the insertion. The tab is partially

embedded into the cowling and turned down for locking into place.

Haven't decided how I am going to cover the tab yet and it really isn't

at the top of my issues list.

|