| This is my strobe power supply leads for

tail strobe, and the electrical leads for the tail light, and the leads for

the electrical trim being fed into the conduit to the rear of the plane.

They are wrapped by a spiral of poly tubing cut on a spiral, you can then

wrap it around the wires and it tries to return to the original size, clamping

the wires together. Since the picture was taken, I have added an intermediate

clamp to the wire bundle to tie it into the horiz. Stab at the recommendation

of my technical counselor. |

|

Control Stops |

|

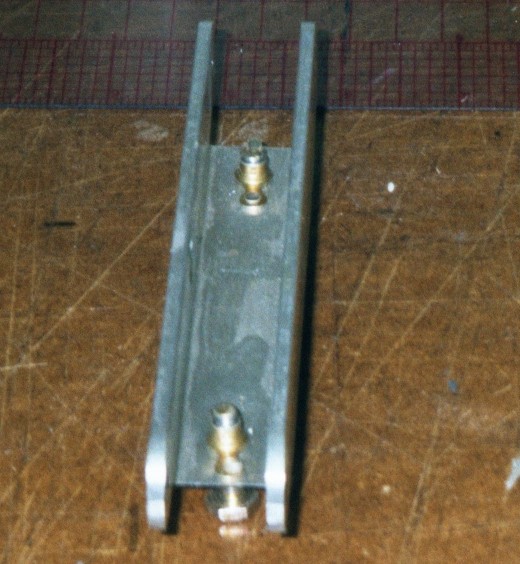

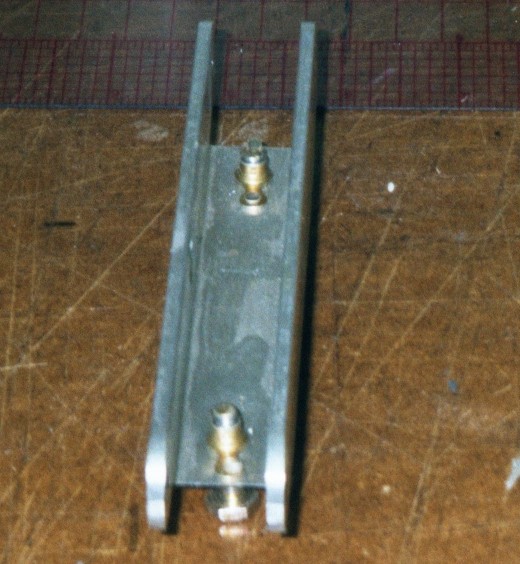

Control Stops

Following the lead of Ray Clegg, I built in adjustable control stops at

the rear rudder idler. In this photo you can see an aluminum stop plate on

the bulkhead. It protects the fiberglass of the bulkhead from the bolt heads

shown below. |

|

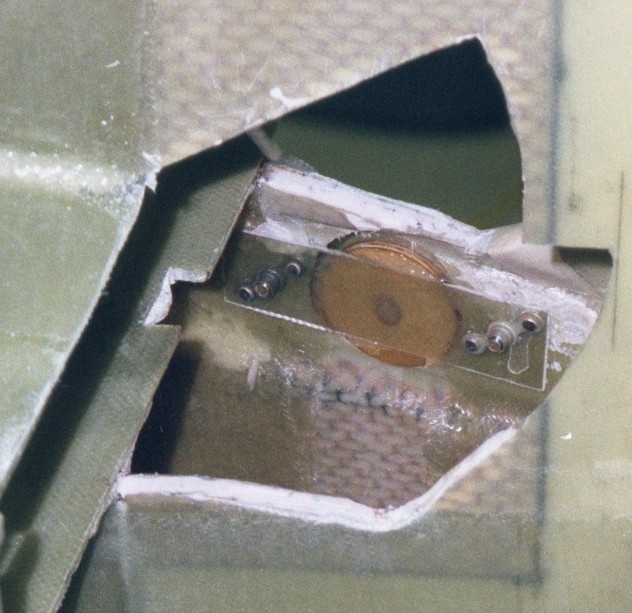

Control Stops, cont’d

Here you can see the nut plates that were riveted onto the inside of the

rudder idler, and the bolts than then stick out the back side. These make

contact with the aluminum plate when full travel is reached. Travel is adjusted

by turning the bolt with a wrench. Adjusting could be a problem of getting

access, so I made another access door. (see below) |

|

| Access door

Here you can see the access hatch just forward of the Hz stab, to allow

inspection and servicing of the 180 bulkhead rudder idler and attachments.

I installed this door after talking to Bob Reed (he has one also) about the

difficulty of us older folks getting back there. |

|

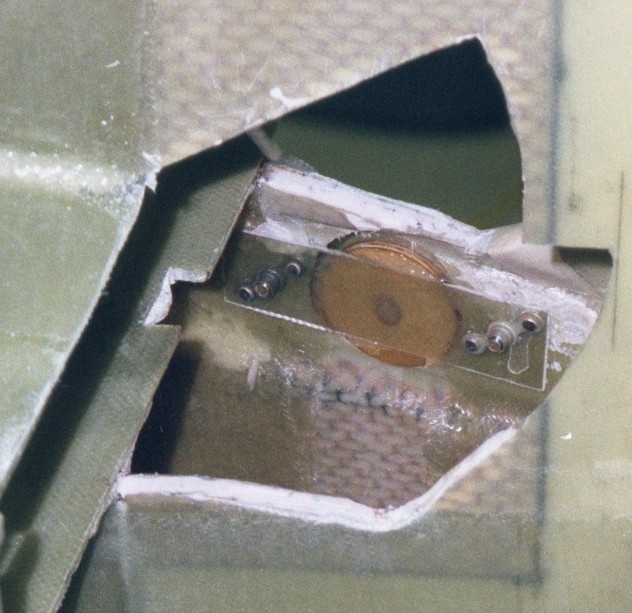

| I cannot seem to get away from access hatches.

Remember the hole that was drilled in the right hand side to allow access

to the elevator horn bolt? I converted the drilled out piece of material

into a small removable hatch to seal that off when not accessing the elevator

bolt. The tongue depressor is temporary, just to hold the plug level with

the surface. The two screws and nutplates hold the cover in place when done.

Still to do – fill the excess gap with micro and smooth it. |

|

| |

|